If you search online for ''custom notebook printing,'' you'll find dozens of short articles listing paper types, binding options, or size charts. Most of them repeat the same surface-level information — and none of them truly help buyers make confident decisions.

This page is different.

This is a pillar resource, created to answer everything a buyer, brand owner, or sourcing manager needs to know before producing custom notebooks at scale.

At Jinguan, we work directly with brands, wholesalers, and corporate buyers who are often confused not by lack of options — but by too many options without context. This guide exists to give that context.

Instead of isolated tips, you'll find:

- Decision logic instead of feature lists

- Manufacturing reality instead of marketing language

- Clear connections between design, cost, durability, and user experience

Table of Contents

- What Custom Notebook Printing Really Means in Manufacturing

- How Notebook Design Decisions Affect Cost, Quality, and Lead Time

- Inner Paper Selection: Writing Experience vs Production Reality

- Notebook Cover Materials: Branding Impact and Structural Differences

- Notebook Size Choices: Standardization vs Differentiation

- Binding Methods in Practice: Strengths, Limits, and Misuse

- Finishing Techniques: Where Perceived Value Is Actually Created

- Custom Notebook Printing for Different Use Cases

- Bulk Production, MOQ, and Long-Term Supply Stability

- How We Approach Custom Notebook Manufacturing at Jinguan

- Conclusion: How to Use This Guide in Real Sourcing Decisions

- FAQs

1. What Custom Notebook Printing Really Means in Manufacturing

Custom notebook printing is not a single process — it is a system of interdependent decisions.

When buyers say ''custom,'' they may mean:

- A logo on the cover

- A specific paper feel

- A premium retail-quality notebook

- Or a cost-controlled promotional item

From a manufacturing perspective, each interpretation leads to completely different production paths.

A notebook is made up of:

- Printed inner pages

- Structural binding

- Cover material + board

- Finishing processes

- Assembly, inspection, and packing

Changing one element often affects three others. This is why treating notebooks like ordinary print products often results in delays, cost overruns, or disappointing quality.

2. How Notebook Design Decisions Affect Cost, Quality, and Lead Time

Design is not just visual — it is technical.

We already covered layout setup, bleed, pagination, and file preparation in ''How to Design a Custom Notebook: A Step-by-Step Guide for Beginners.'' Here, we go one level higher.

Design choices that directly affect manufacturing:

- Full-bleed vs non-bleed layouts

- Page count divisibility (especially for stitched notebooks)

- Ink coverage density

- Margin allowance for binding

Common buyer mistake:

Designing first, then asking whether it's producible.

From our experience, early design validation can:

- Reduce sampling rounds by 30–40%

- Prevent binding incompatibility

- Avoid late-stage layout rework

A good design is not just attractive — it is manufacturing-aware.

3. Inner Paper Selection: Writing Experience vs Production Reality

Paper is often chosen emotionally — smoothness, thickness, color — but it must also be chosen structurally.

Writing experience factors:

- Smoothness (coated vs uncoated)

- Ink absorption

- Ghosting and bleed-through

- Color temperature (white vs cream)

Manufacturing factors:

- Paper grain direction

- Folding behavior

- Binding compatibility

- Cost fluctuation by GSM

For example:

- Thicker paper improves quality perception but reduces max page count

- Softer paper improves writing feel but may curl under humidity

This is why paper choice must be aligned with:

- Notebook purpose

- Binding method

- Target price range

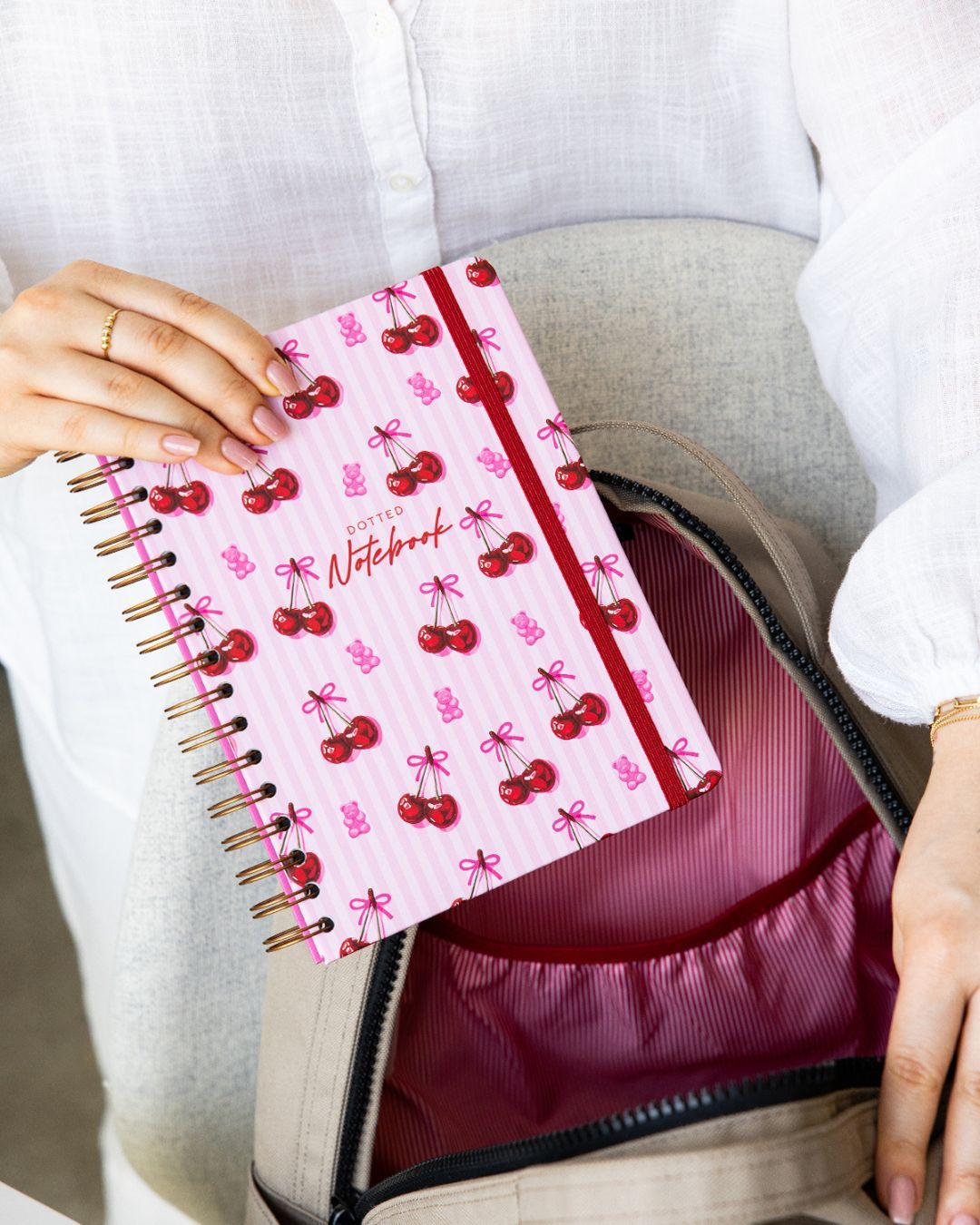

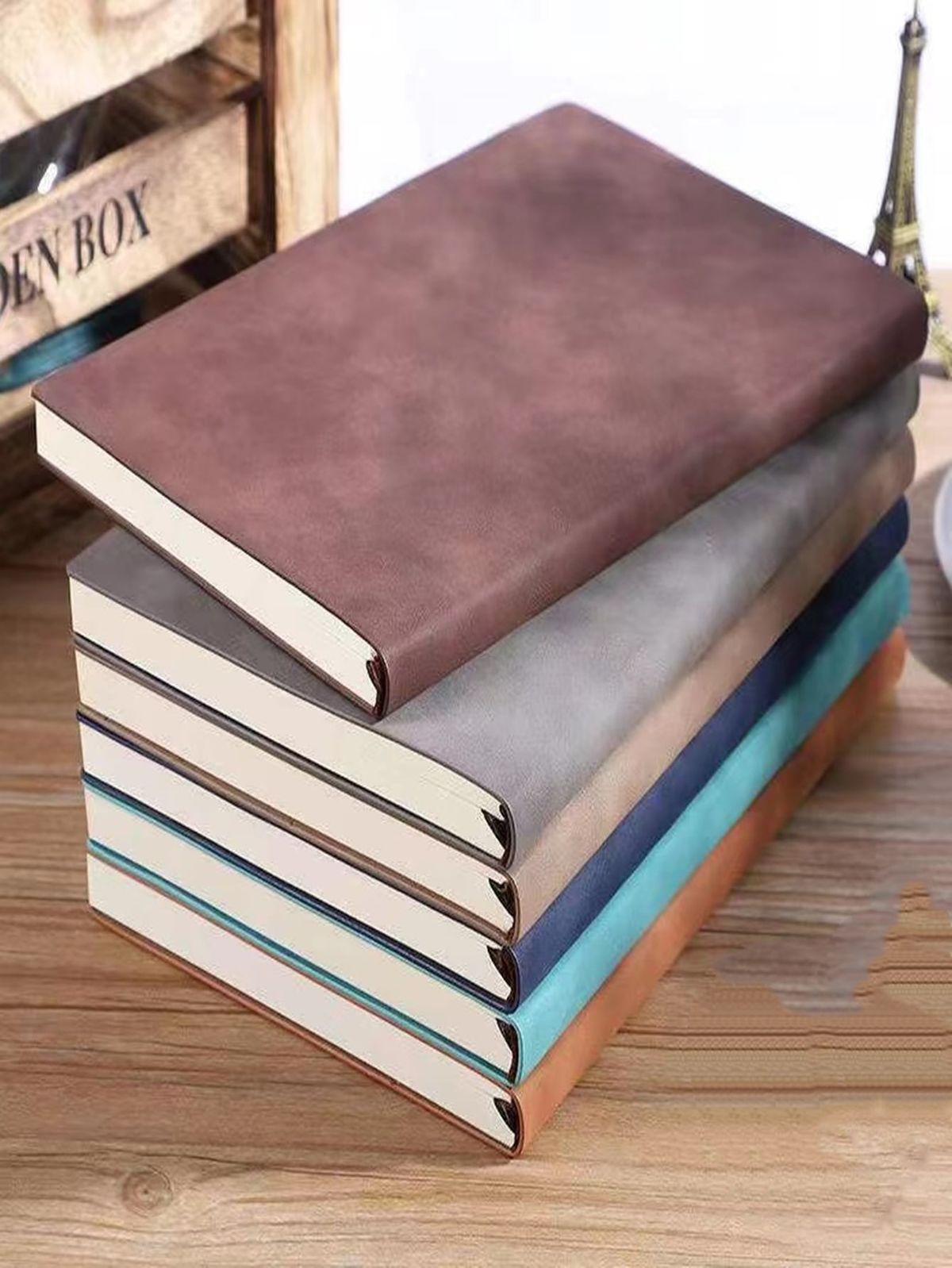

4. Notebook Cover Materials: Branding Impact and Structural Differences

The cover is the most visible branding surface, but also a structural component.

Visual branding role:

- Color consistency

- Texture perception

- Logo presentation (foil, emboss, print)

Structural role:

- Protection

- Resistance to bending

- Binding support

We see buyers often choose covers purely based on appearance, then discover:

- Cracking on spines

- Warping during shipping

- Weak adhesion with certain bindings

Cover material should never be selected in isolation — it must work with the binding and inner paper.

5. Notebook Size Choices: Standardization vs Differentiation

Notebook size decisions affect:

- User comfort

- Shipping efficiency

- Printing imposition

- Cost per unit

Standard sizes (A5, A4, B5) exist because they are:

- Easier to produce

- Easier to scale

- Easier to stock

Custom sizes can differentiate your brand — but they must justify:

- Tooling cost

- Lower material efficiency

- Potential MOQ increases

In large-scale notebook printing, size is a strategic decision, not just an aesthetic one.

6. Binding Methods in Practice: Strengths, Limits, and Misuse

We explored binding types in detail in ''Notebook Binding Methods Explained: Spiral, Stitching, Perfect Binding & Hardcover (2025 Guide).''

Here, let's focus on misuse.

Common mismatches we see:

- Too many pages for saddle stitching

- Heavy covers paired with weak binding

- Decorative bindings chosen for functional notebooks

Binding determines:

- Durability

- Writing comfort

- Shelf life

- Perceived value

A notebook that ''looks premium'' but falls apart is worse than a simple one that lasts.

7. Finishing Techniques: Where Perceived Value Is Actually Created

Finishing is where cost turns into perception.

Two notebooks with identical paper and binding can feel completely different because of:

- Foil stamping placement

- Depth of embossing

- Matte vs gloss lamination

- Edge treatments

We expanded on this in ''Custom Notebook Printing Options Explained: Paper, Cover, Size & Finishing.''

From a manufacturer's perspective, finishing should:

- Highlight branding, not overpower it

- Stay consistent across batches

- Align with notebook usage frequency

Premium finishing is effective only when used with restraint.

8. Custom Notebook Printing for Different Use Cases

Different use cases demand different priorities:

- Promotional notebooks → cost efficiency, brand visibility

- Retail notebooks → durability, tactile experience

- Corporate notebooks → professional appearance, consistency

- Educational notebooks → writing comfort, structural strength

Treating all notebooks the same leads to misaligned expectations.

9. Bulk Production, MOQ, and Long-Term Supply Stability

Bulk notebook printing is not just about lower unit cost.

It involves:

- Stable material sourcing

- Repeatable quality standards

- Controlled production schedules

MOQ exists to protect:

- Print consistency

- Binding strength

- Cost structure

A reliable manufacturer focuses on long-term scalability, not one-off orders.

10. How We Approach Custom Notebook Manufacturing at Jinguan

From our perspective, a successful project means:

- Fewer surprises

- Predictable quality

- Repeatable results

We work with clients to:

- Validate designs early

- Recommend material combinations

- Balance customization with scalability

We don't believe notebooks should be overdesigned — they should be well-designed for real use.

11. Conclusion: How to Use This Guide in Real Decisions

This guide is not meant to be read once and forgotten.

Use it to:

- Compare supplier recommendations

- Validate design decisions

- Understand cost differences

- Build better notebooks over time

A good notebook is not accidental — it is the result of informed decisions.

12. FAQs

Q1: What is the most cost-effective custom notebook option?

A5 size, woodfree paper, and spiral binding remain the most economical combination for bulk orders.

Q2: Can I mix different paper types in one notebook?

Yes, but it increases complexity and requires careful binding planning.

Q3: What affects notebook durability the most?

Binding method and cover structure, more than paper thickness.

Q4: How early should I involve a manufacturer?

Ideally at the design stage, before finalizing specifications.