Notebook binding is not a minor production detail — it defines how your product will be used, perceived, stored, and sold. As someone who helps brands and designers develop custom stationery every day, I know that the right binding method directly affects durability, user experience, production cost, minimum order quantity (MOQ), lead time, and ultimately how well your notebook represents your brand. At Jinguan, we work with clients worldwide to select the ideal binding, paper, cover, finishing, and packaging combinations that meet marketing goals and budget constraints.

This 2025 guide explains the most common binding methods—spiral (coil/wire-o), stitching (saddle stitch / thread sewn), perfect binding (glue), hardcover (case binding)—and dives deeper into production considerations, finishing options, eco-friendly choices, quality control, sampling, cost drivers, and scenario-based recommendations for promotional notebooks, retail journals, corporate gifting, and educational products.

Why binding matters: beyond aesthetics

Binding affects more than appearance. It determines:

- How the notebook opens and lies on a desk

- The longevity of the product under repeated use

- Printing and finishing choices you can apply to the spine and cover

- Shipping and packaging requirements

- Price per unit and overall MOQ viability

- Environmental impact (recyclability, materials used)

When I consult with customers at Jinguan, the first questions I ask are: Who is the end user? How will it be used? What is your target price per unit? How quickly do you need the product? Answers to these dictate the binding choice more than aesthetics alone.

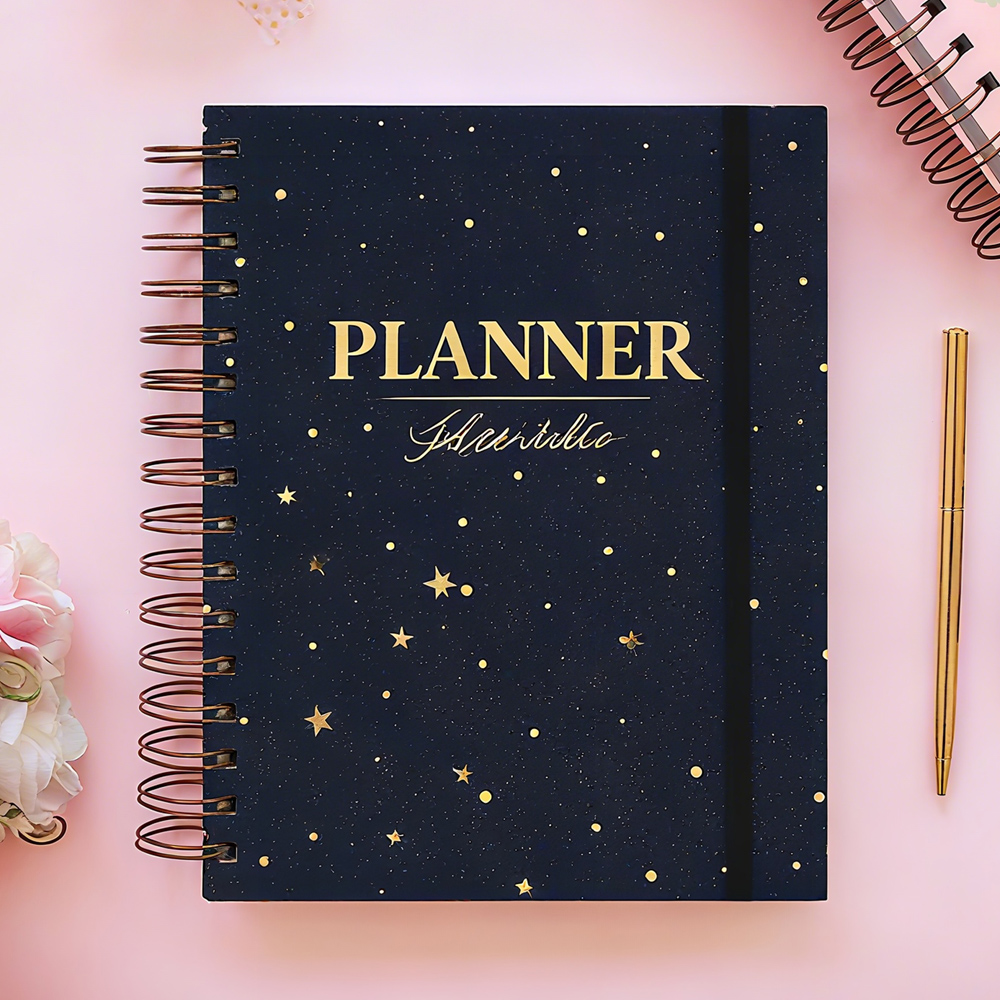

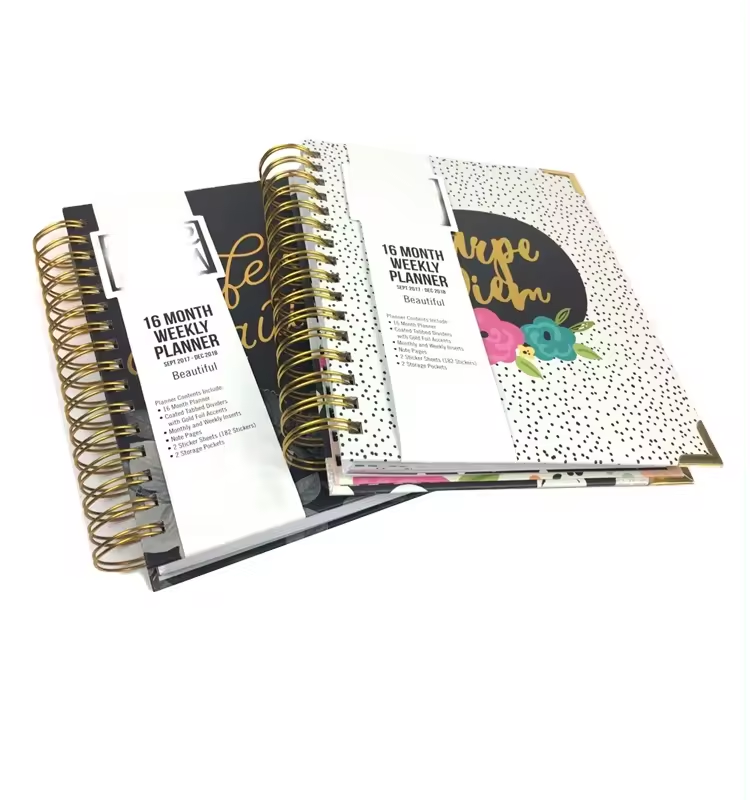

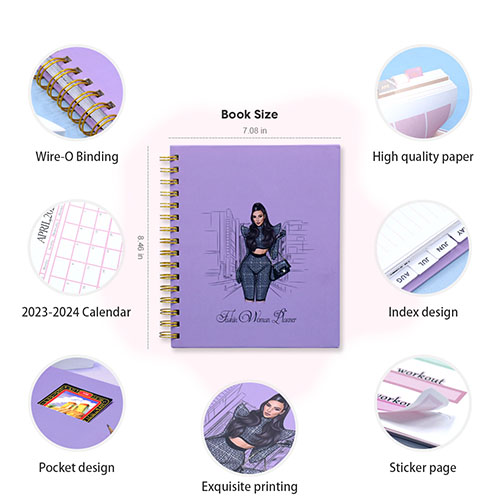

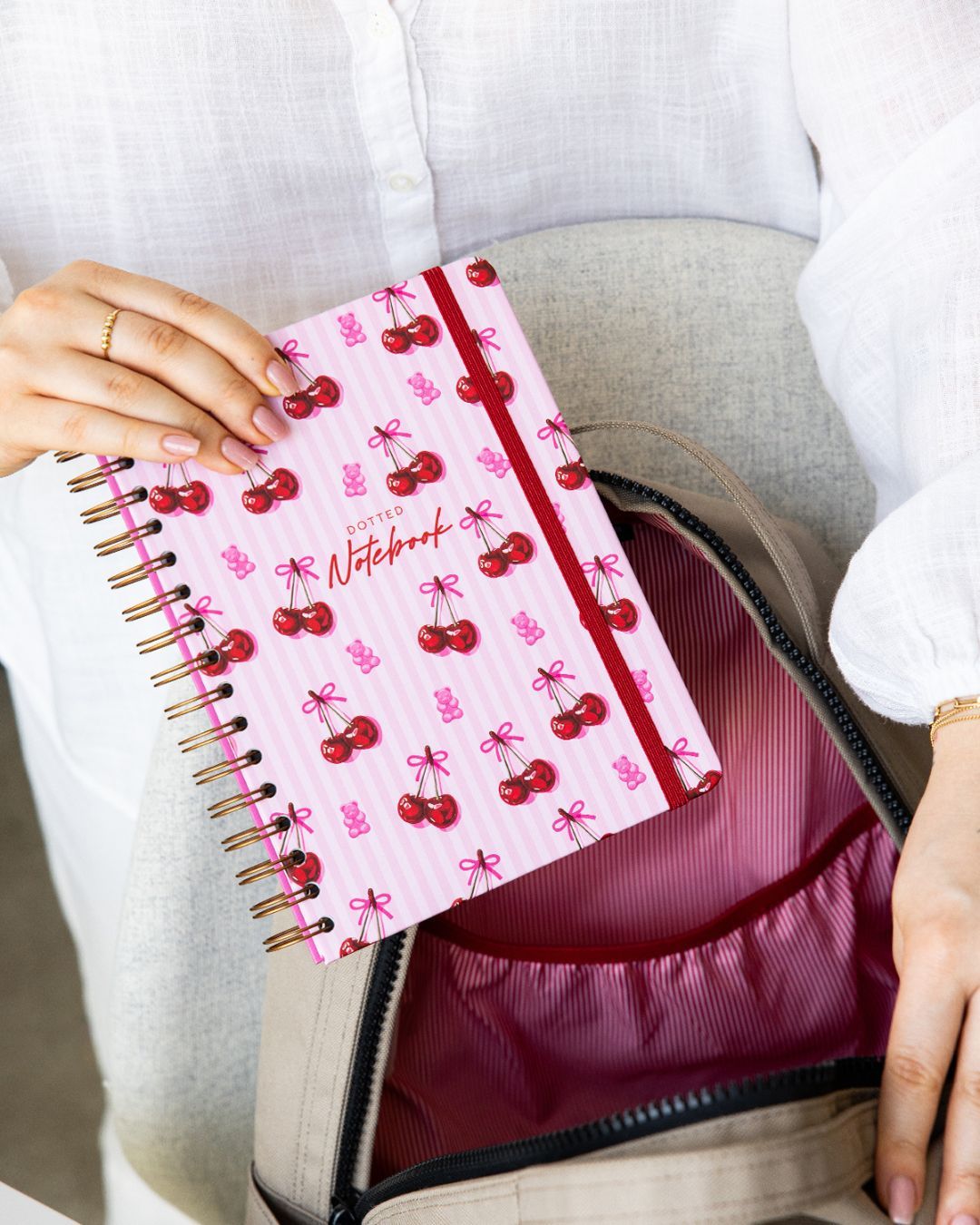

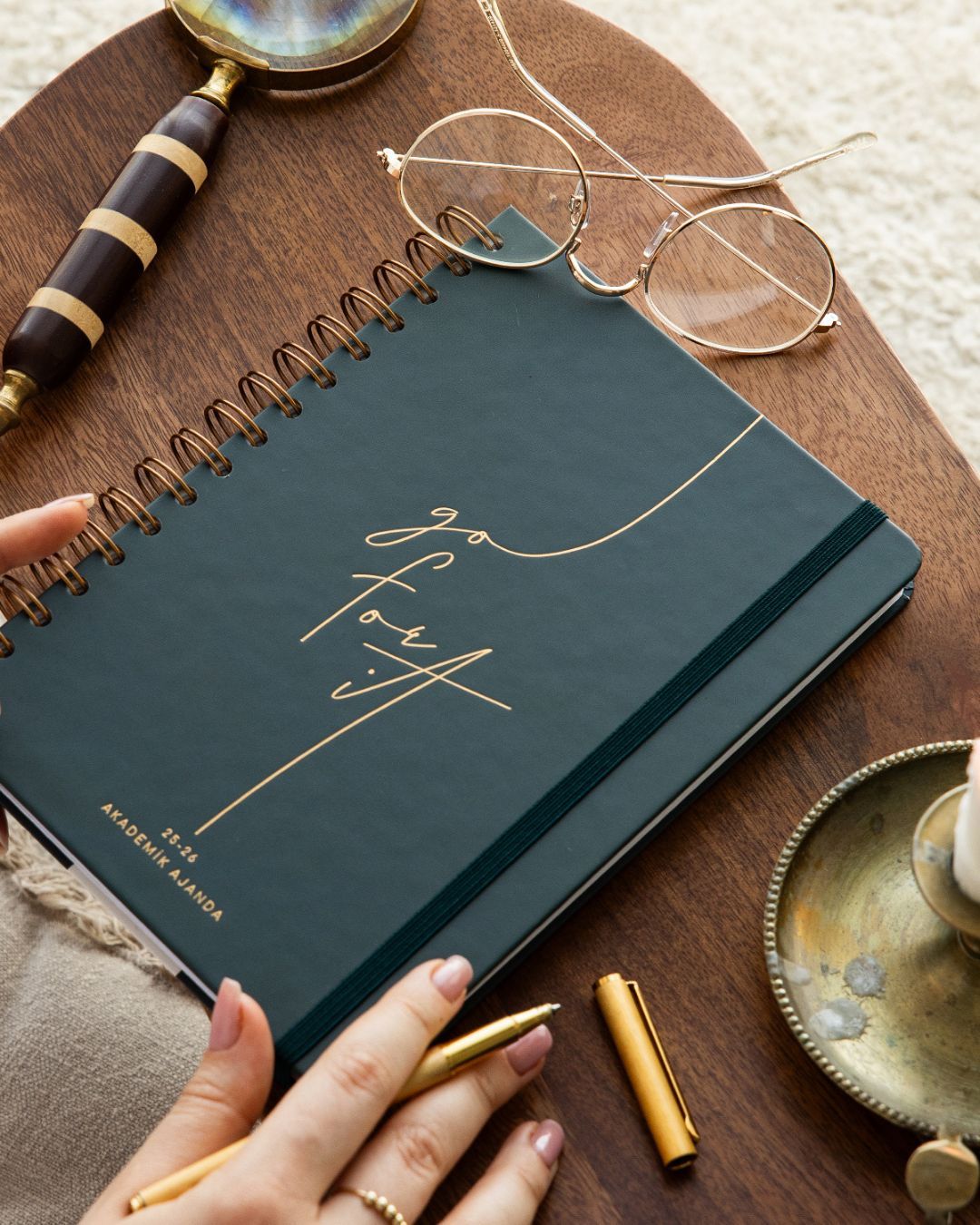

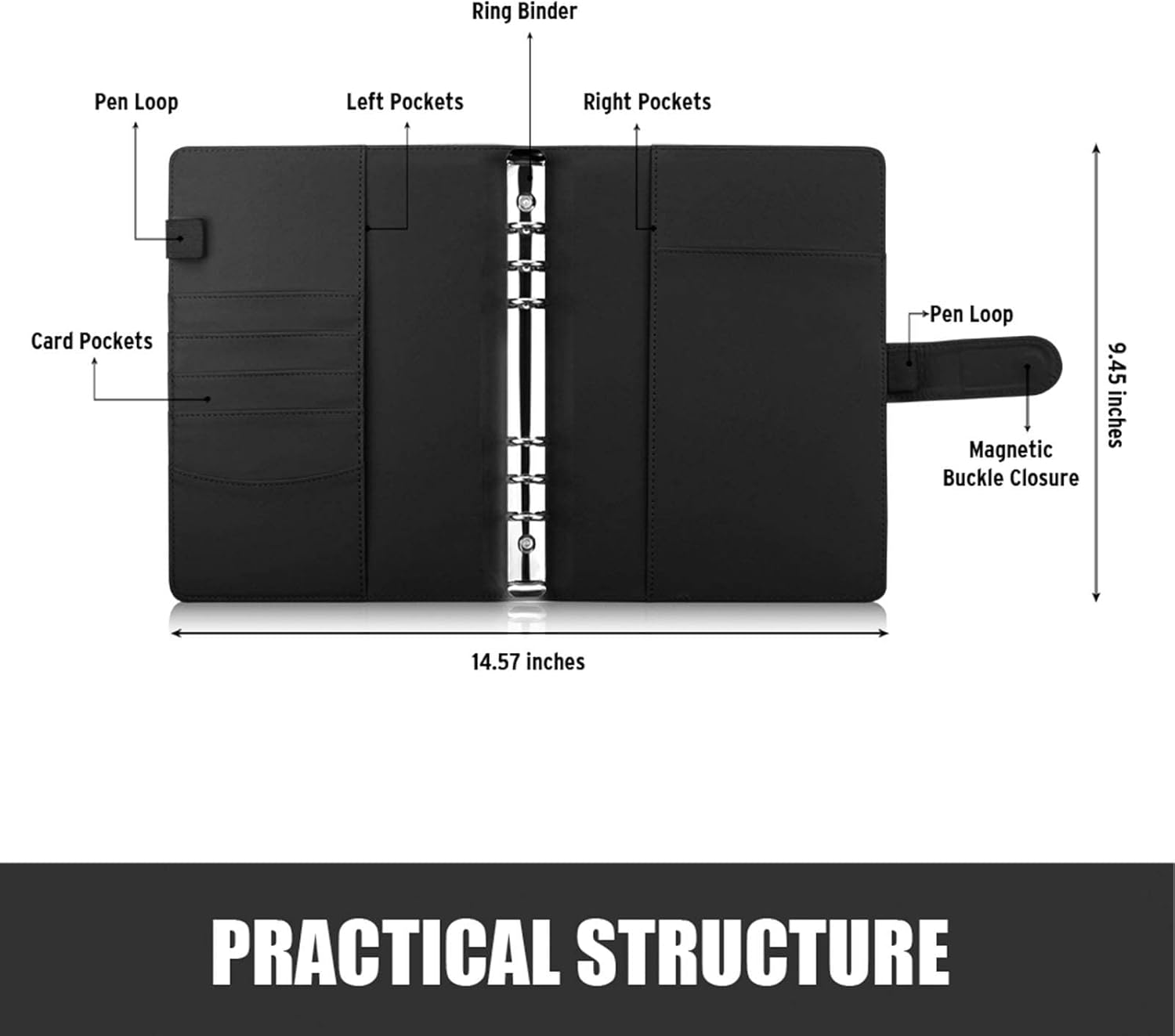

Spiral Binding (Coil / Wire-O): usability first

Spiral binding (metal wire or plastic coil) is extremely popular because it allows the notebook to open flat or fold back on itself. Holes are punched along the margin and a coil runs through them. Wire-O is a metal double-loop that looks neater and is more robust than single-coil plastic.

Advantages

- Opens flat and rotates 360°, excellent for note-taking, sketching, and instructional materials.

- Durable and repairable; coils can be replaced in some cases.

- Works with a wide range of page counts (from thin to very thick).

- Offers color-matching of coils for brand identity.

- Fast production and predictable lead times.

Considerations

- Coil ends must be crimped to avoid catching.

- Metal coils add slight weight and marginally higher cost than stitched books.

- For retail packaging, spirals can catch on other products unless individually wrapped.

Production notes

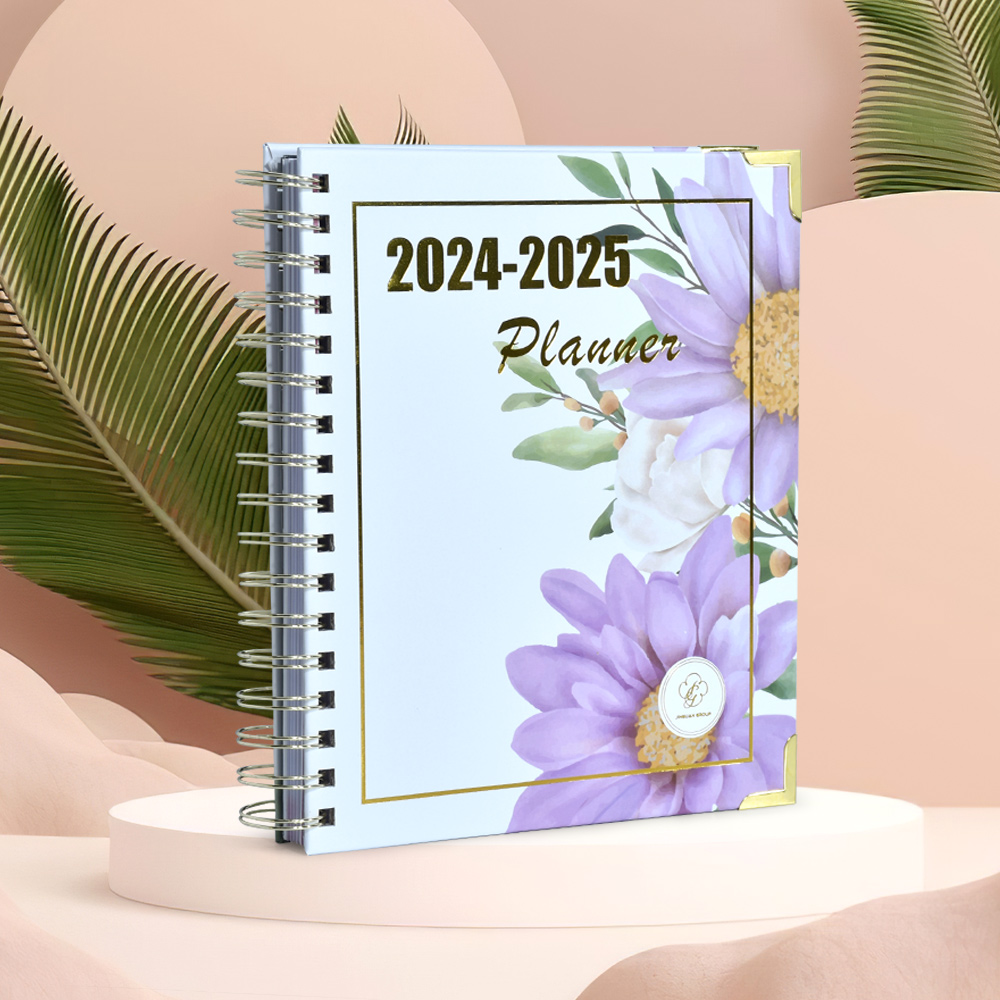

At Jinguan, we suggest using Wire-O for corporate planners where a premium look and lay-flat performance matter. Plastic coils are great for lightweight giveaway notebooks. Typical MOQ for spiral-bound notebooks can be relatively low (from a few hundred pieces), depending on other customization (cover foil, custom die-cutting).

Best uses

Workbooks, training manuals, planners, academic notebooks, sketch pads.

Stitching Binding (Saddle Stitch / Thread Sewn): economical & clean

Stitching binding holds folded signatures with staples (saddle stitch) or thread. It’s one of the most economical methods and has minimal material waste.

Advantages

- Low cost and very fast turnaround.

- Lightweight and mail-friendly.

- Minimal spine area—clean, simple look.

- Thread-sewn finishes offer more durability while keeping a minimal aesthetic.

Considerations

- Not suitable for very high page counts; recommended for ≤80 pages for saddle stitch.

- Doesn't always lay perfectly flat like spiral.

- Less premium perception compared to perfect or hardcover methods.

Production notes

Saddle-stitched notebooks are the go-to for event giveaways and seasonal promotional items. If durability is a concern, we recommend thread-sewn signatures (stronger) which still remain cost-effective. MOQs are typically friendly to smaller runs, and turnaround can be very fast—ideal for tight deadlines.

Best uses

Event giveaways, slim catalogs, pocket notebooks, short manuals.

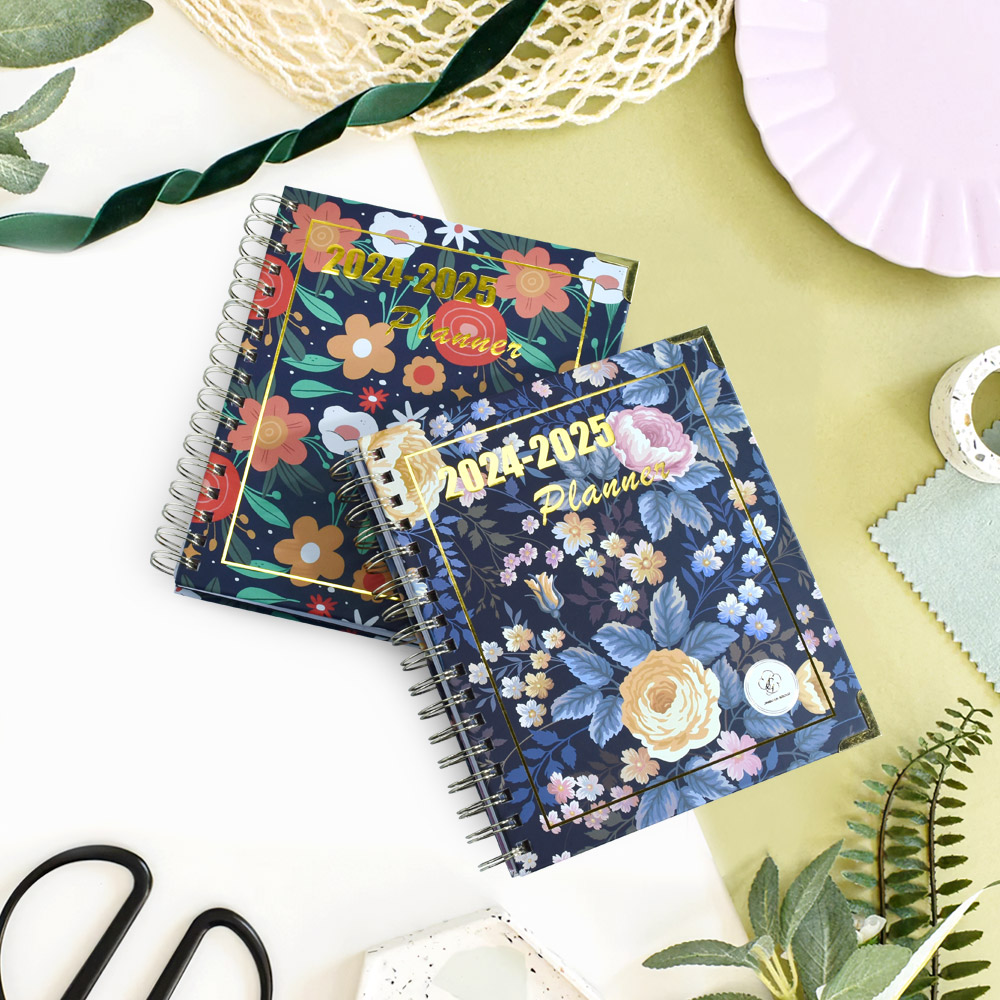

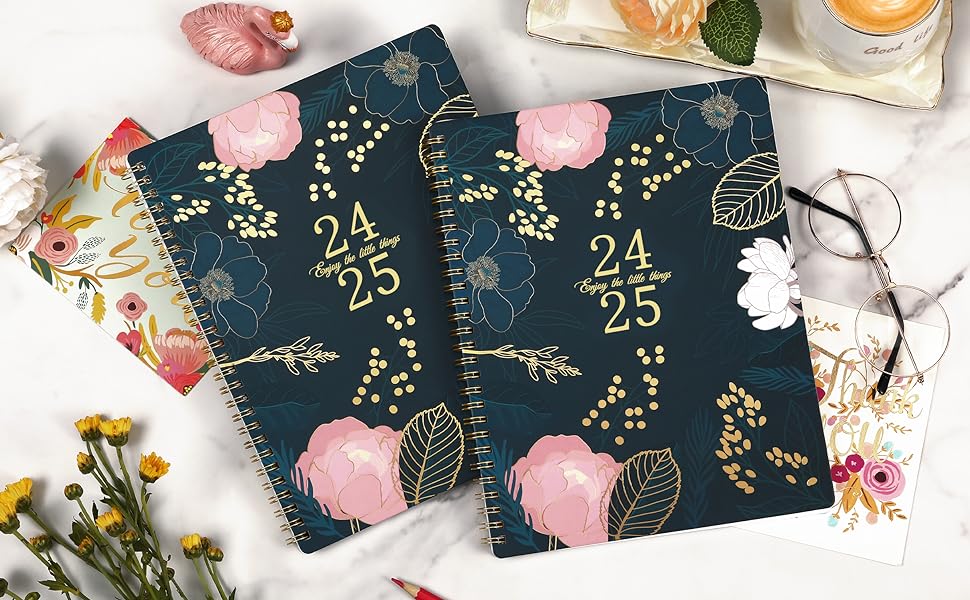

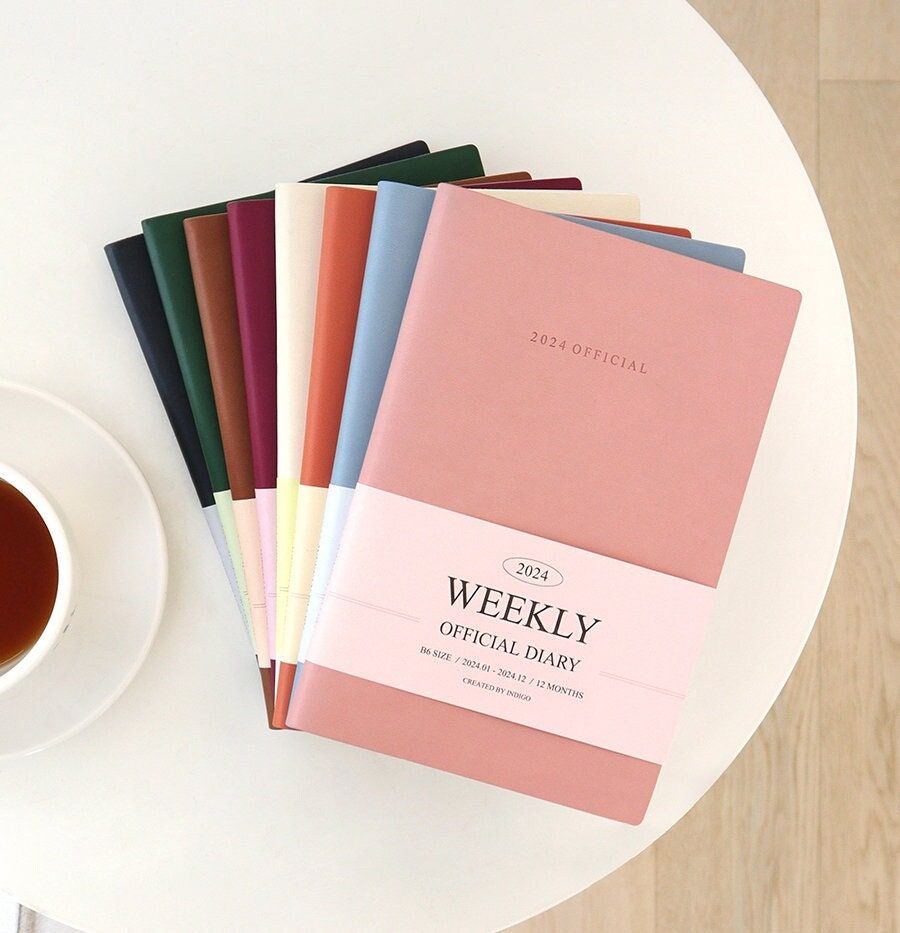

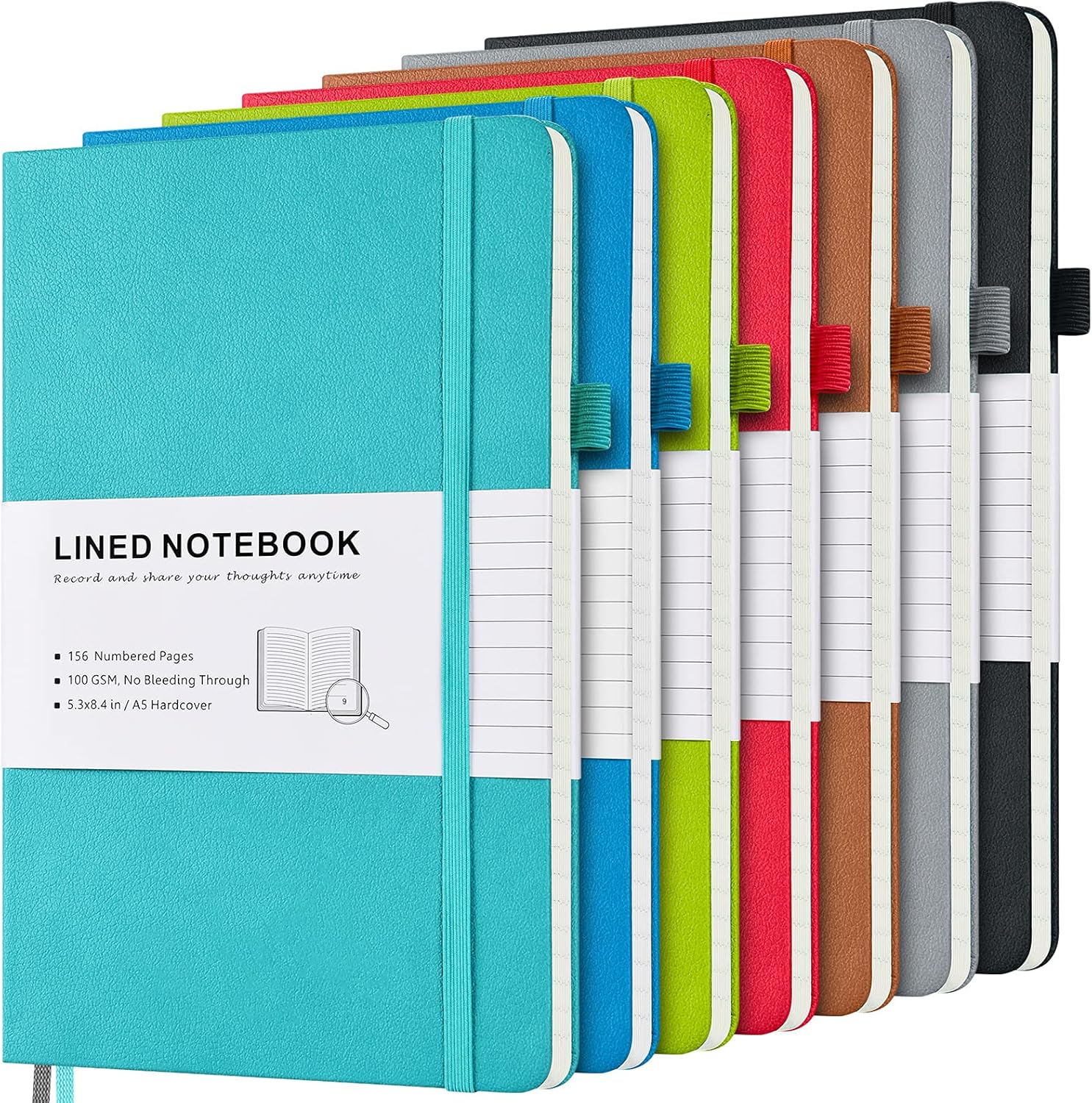

Perfect Binding (Thermal / PUR Glue): retail-friendly

Perfect binding glues single pages at the spine and wraps them with a softcover. This method gives a square spine and a bookstore-style appearance.

Advantages

- Clean, professional appearance with full-spine printing options.

- Suitable for thicker notebooks, planners, and retail products.

- Great for full-color cover treatments and large print runs.

Considerations

- Typically does not open completely flat (can be mitigated with sewn signatures + glue).

- Low-quality adhesives risk cracking over time—use PUR or high-grade EVA glue for longevity.

- Usually higher production cost than saddle-stitch, but less than hardcover.

Production notes

At Jinguan, we prefer PUR glue for notebooks that need long life and frequent opening. Perfect binding works well when you want printed spine text for retail shelf presence. MOQ and lead times depend on customized cover wraps and special coatings (matte lamination, soft-touch, UV spot), but are usually cost-effective for medium to large batches.

Best uses

Retail journals, corporate notebooks, planners, educational materials with moderate to high page counts.

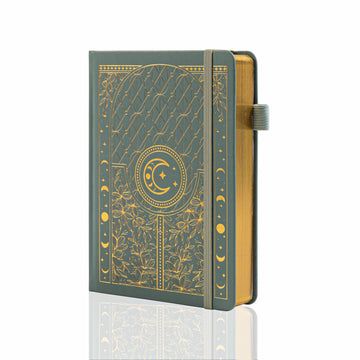

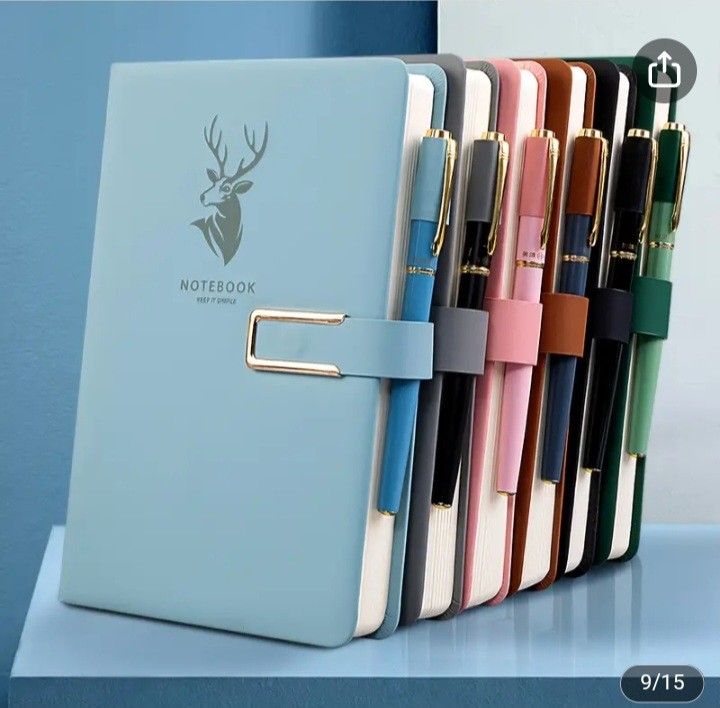

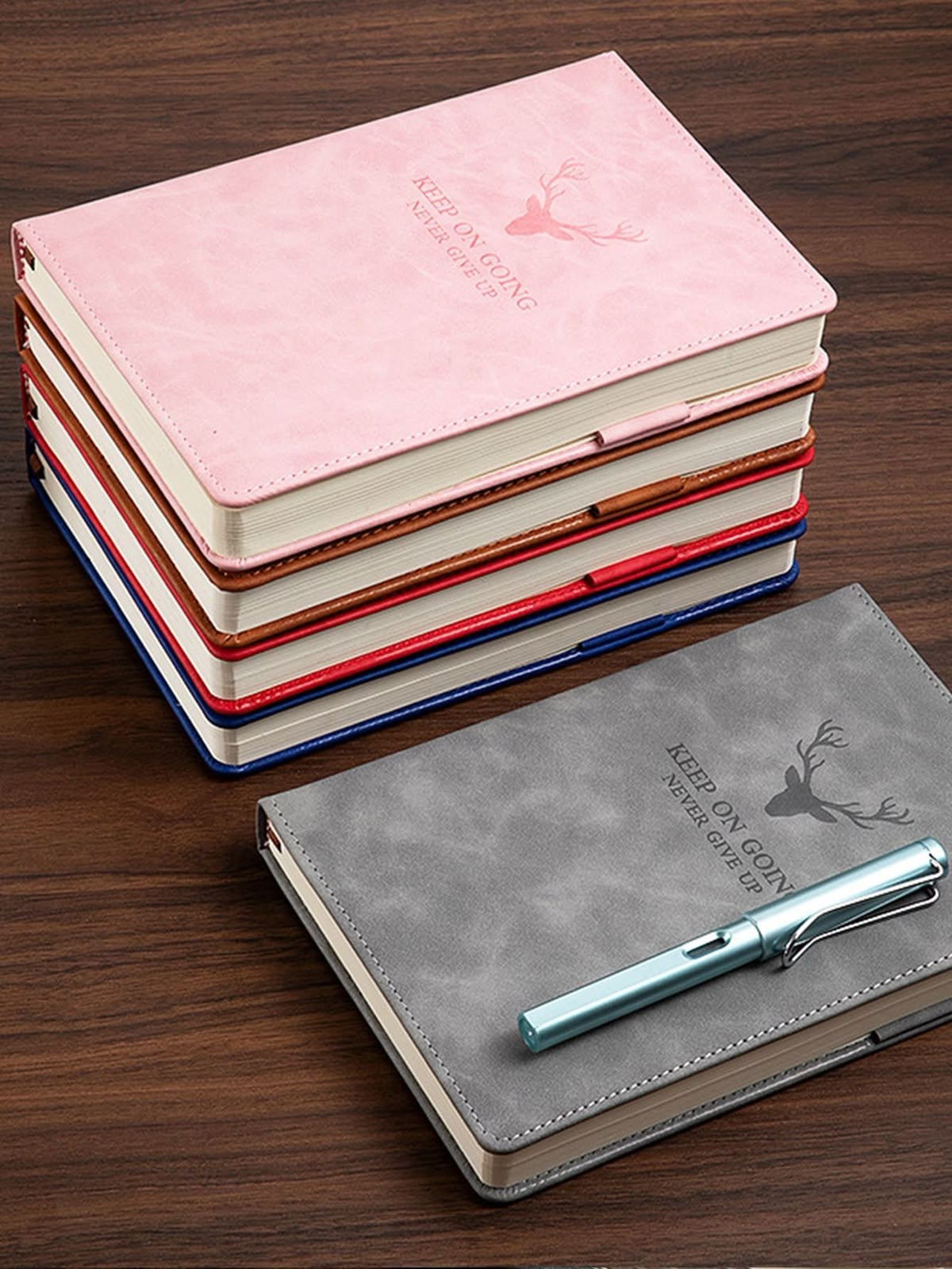

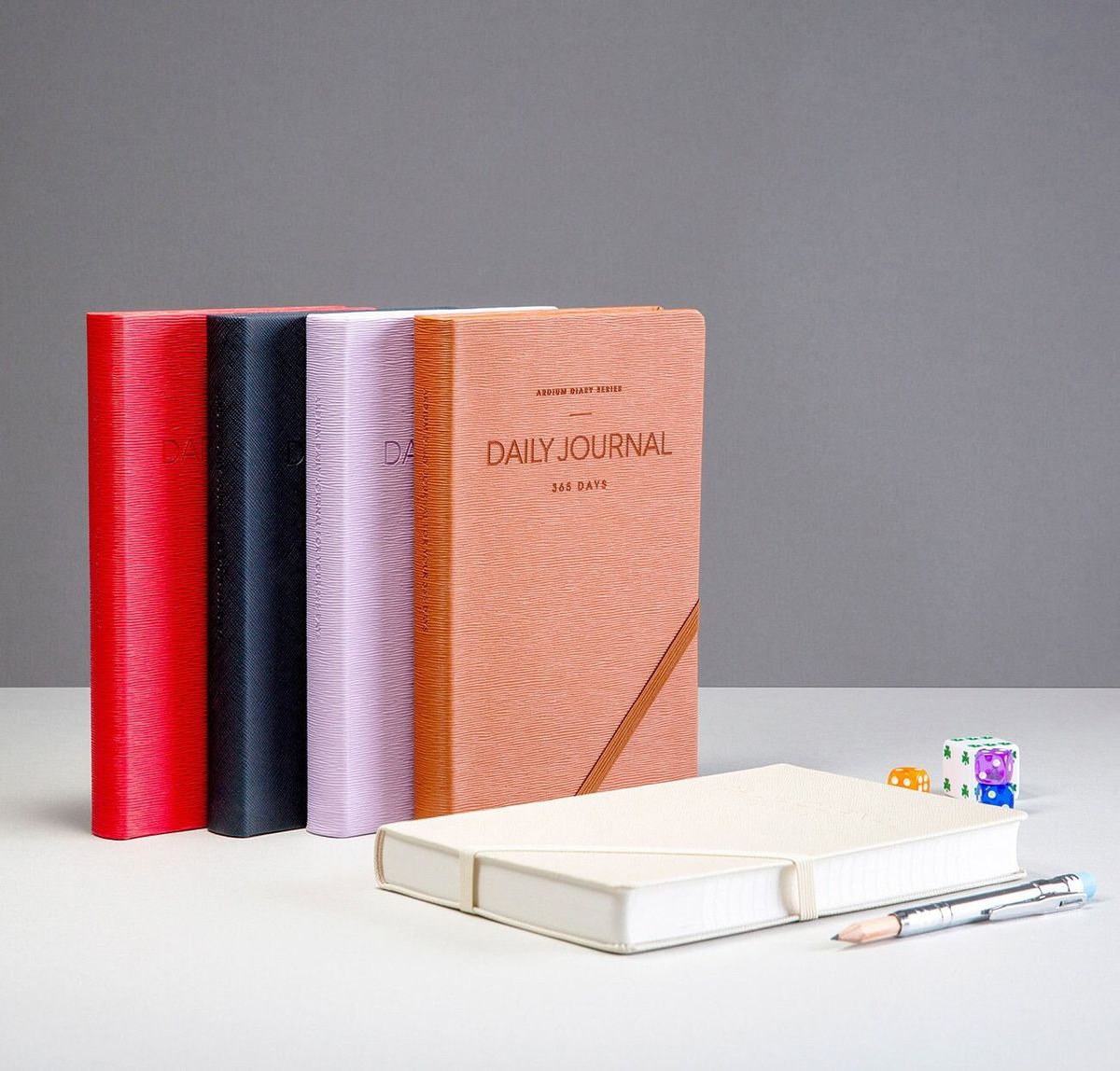

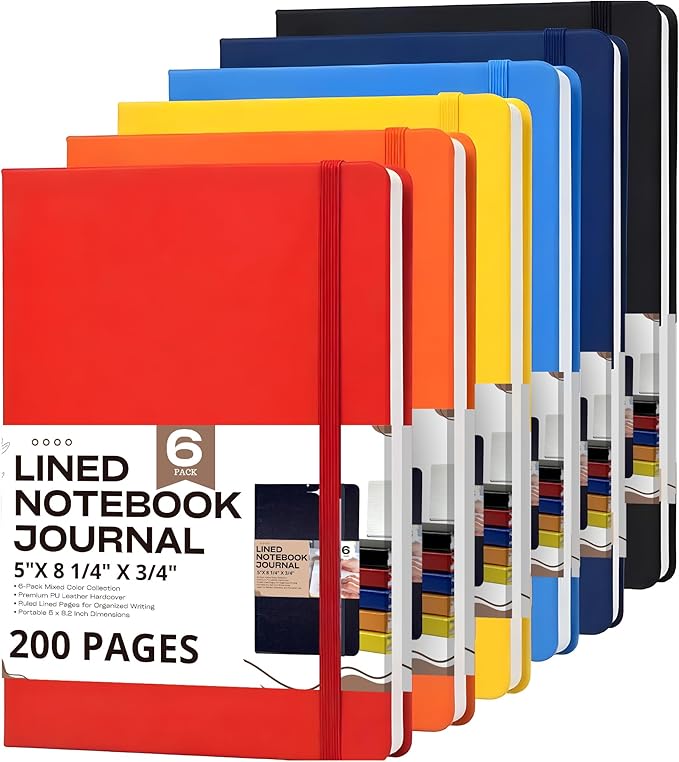

Hardcover Binding (Case Binding): premium & durable

Hardcover (case binding) attaches sewn or glued signatures to rigid covers made from chipboard wrapped with cloth, paper, or PU. This is the top-tier option for durability and brand prestige.

Advantages

- Superior durability and protection.

- High perceived value — ideal for gifts and premium retail.

- Supports advanced finishing: foil stamping, embossing, debossing, textured cloth.

- Excellent for archival or keepsake products.

Considerations

- Higher unit cost and shipping weight.

- Longer lead time due to casing-in, endpapers, and finishing steps.

- Requires more complex tooling for deboss/foil.

Production notes

Hardcover notebooks usually have higher MOQs because of tooling and material setup, but they deliver strong ROI when used as executive gifts or flagship retail SKUs. We advise clients to invest in high-quality endpapers and binding threads to ensure longevity—details visible to discerning customers.

Best uses

Executive journals, gift books, luxury planners, keepsakes.

Sewn Binding vs. Glue-only: why sewing matters

Sewn (section-sewn) binding stitches groups of pages together before gluing or casing them. Sewing improves durability and allows the book to open flatter compared to glue-only perfect binding. For planners and notebooks designed for heavy daily use, sewn binding combined with a case or high-quality perfect-binding adhesive is the best practice.

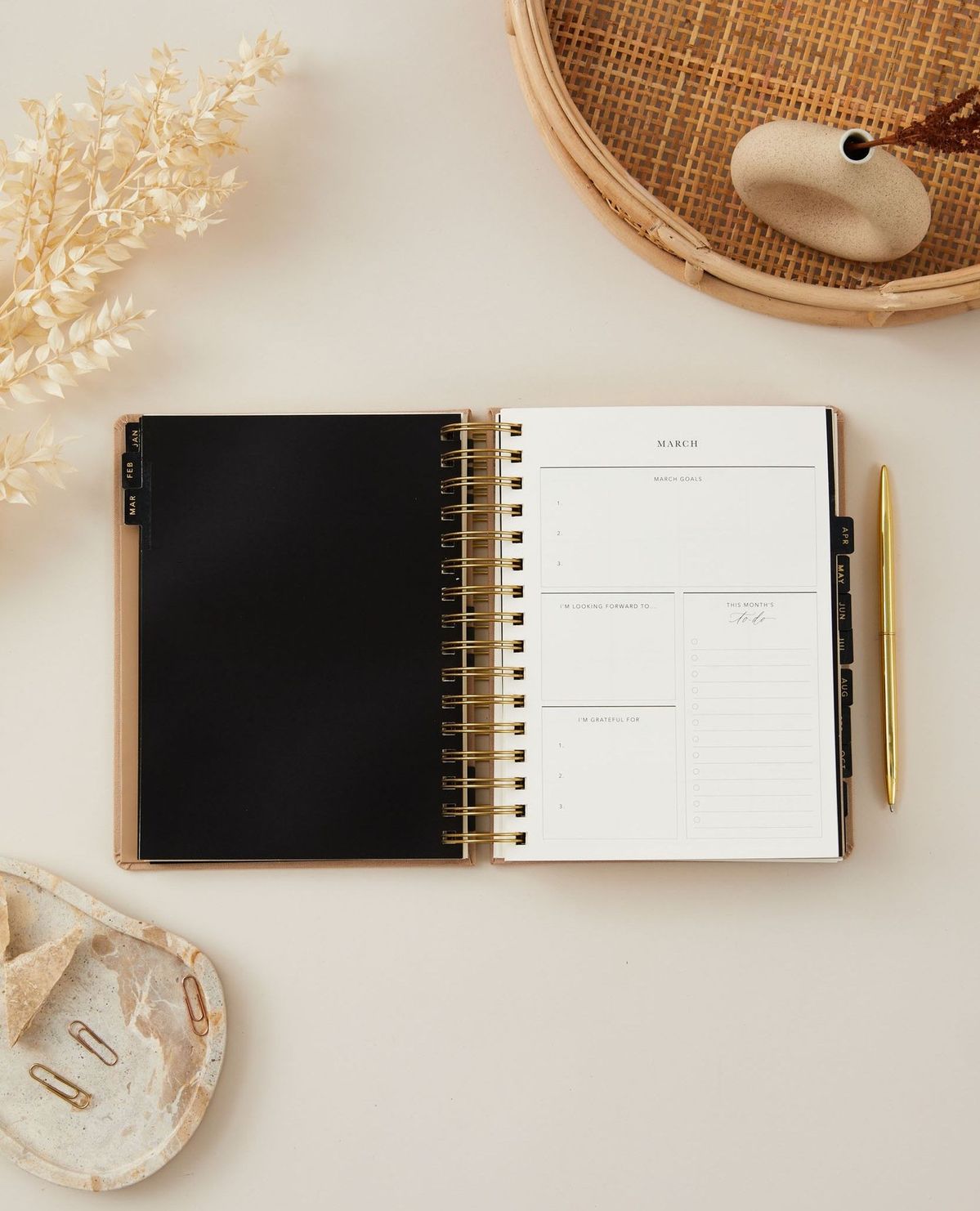

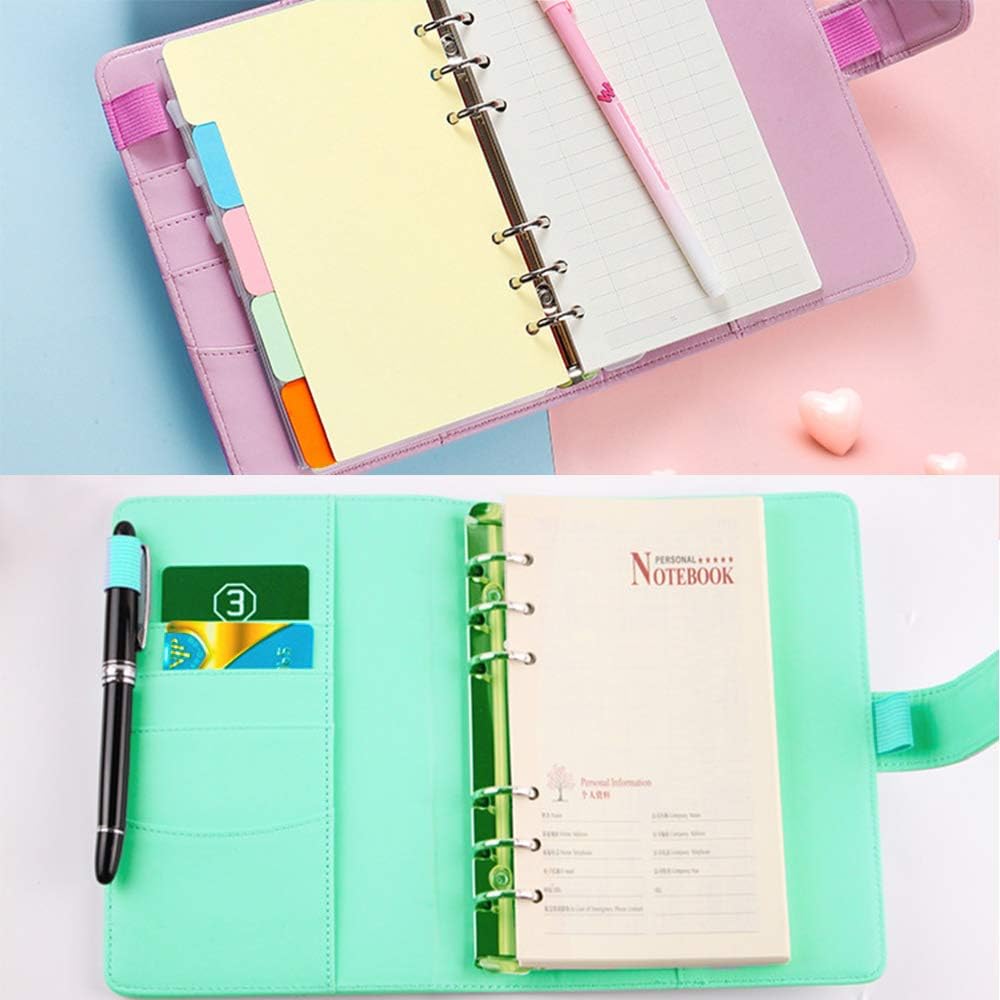

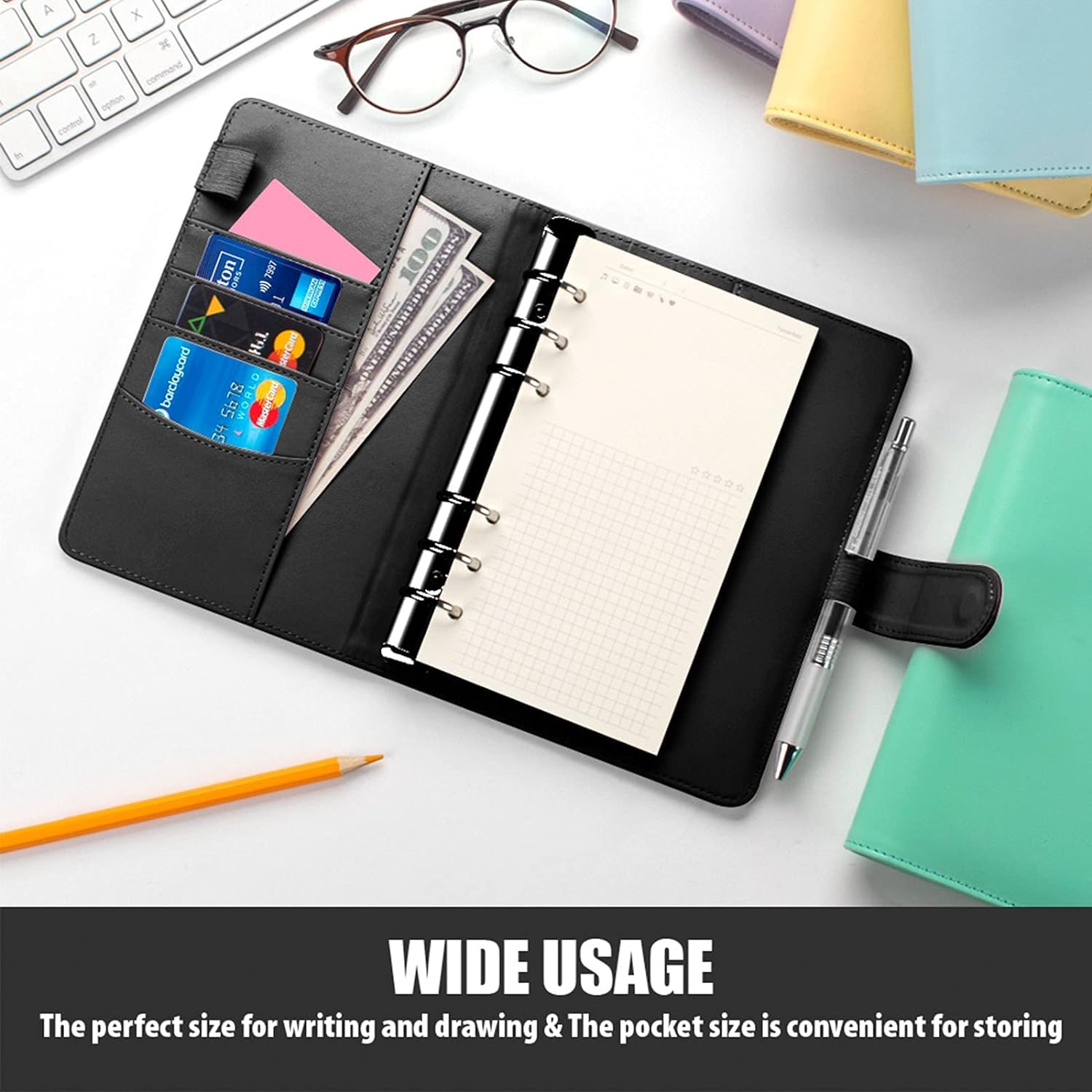

Finishing, cover materials & printing processes to consider

Choosing binding is inseparable from cover finishing and printing:

- Cover materials: kraft paper, coated art paper, linen, PU leather, vegan leather.

- Finishes: matte lamination, gloss lamination, soft-touch, spot UV, aqueous coating, foil stamping, debossing/embossing.

- Printing methods: digital printing (low MOQ, variable data), offset (best color fidelity and lower cost at scale), screen printing (special effects).

- Inners: lined/dotted/grid/plain, perforations, numbered pages, custom templates, colored edges.

We often advise brands to balance aesthetic finishes (foil, emboss) with production cost and MOQ targets.

Sustainability & eco-options

Sustainability is no longer optional. Brands ask for FSC-certified paper, recycled covers, soy-based inks, and recyclable coils. At Jinguan, we offer recycled paper options, eco coatings, and guidance to reduce carbon footprint while maintaining product quality.

Quality control, sampling & lead times

Quality control is critical. We recommend:

- Ordering physical samples before mass production (prototype, pre-production sample).

- Checking color proofs, paper GSM, binding strength, and finishing details.

- Discussing acceptable tolerances for punch alignment and coil crimps.

Typical lead times:

- Saddle stitch / small runs: 1–2 weeks (after artwork approval)

- Spiral binding: 2–3 weeks

- Perfect binding: 3–4 weeks

- Hardcover: 4–6+ weeks depending on finishing and packaging

MOQs vary by method, materials, and finishing. We can often accommodate smaller MOQs for digital printing projects, while offset and hardcover require larger runs to be cost-efficient.

Cost drivers

Major cost drivers include paper GSM, cover material, finishing (foil/lamination), binding method, color pages vs. black-and-white, and packaging. Spiral and saddle stitch typically lower cost; hardcover and heavy finishing increase per-unit price.

Recommendations by scenario

- Event giveaway or mass promo: saddle stitch or low-GSM spiral, simple cover, OPP bag packaging.

- Corporate training or workshop: spiral with durable coil, custom inner templates, optional tabs.

- Retail journal / merchandise: perfect binding with quality cover lamination or soft-touch and printed spine.

- Executive gift or subscription box: hardcover with foil stamping, sewn signatures, premium endpapers.

- Sketchbook / artist pad: heavy inner paper (120–200 gsm) + spiral binding for flat use.

Conclusion

Choosing the right binding method is a strategic decision that balances function, cost, branding, and sustainability. From the flexible usability of spiral notebooks to the economical saddle stitch, the retail-ready perfect binding, and the premium hardcover, each method has its role.

At Jinguan, we partner with customers from concept to delivery—helping with binding selection, paper and cover choices, finishing options, sample approvals, MOQ planning, and quality control. If you're planning a custom notebook project, I'm happy to review your brief and recommend the most cost-effective, brand-appropriate binding solution.