What is Digital Printing? The latest definition in 2025.

Digital Printing

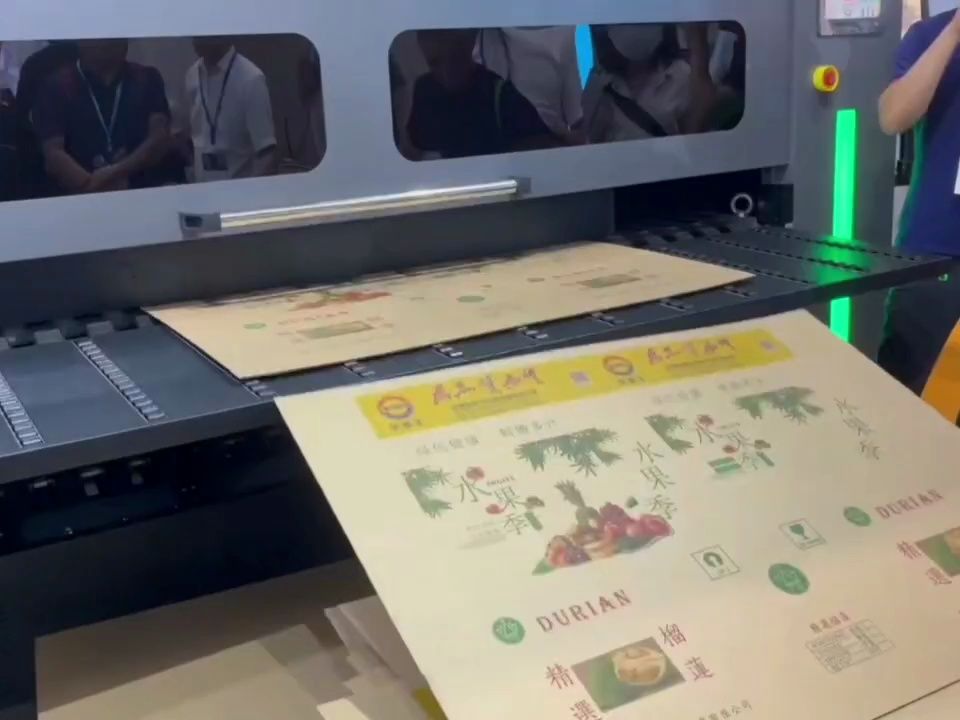

Digital printing is a modern print method where images from digital files are printed directly onto media without platesIt enables rapid, short-run, on-demand printing of personalized and variable-data jobs.

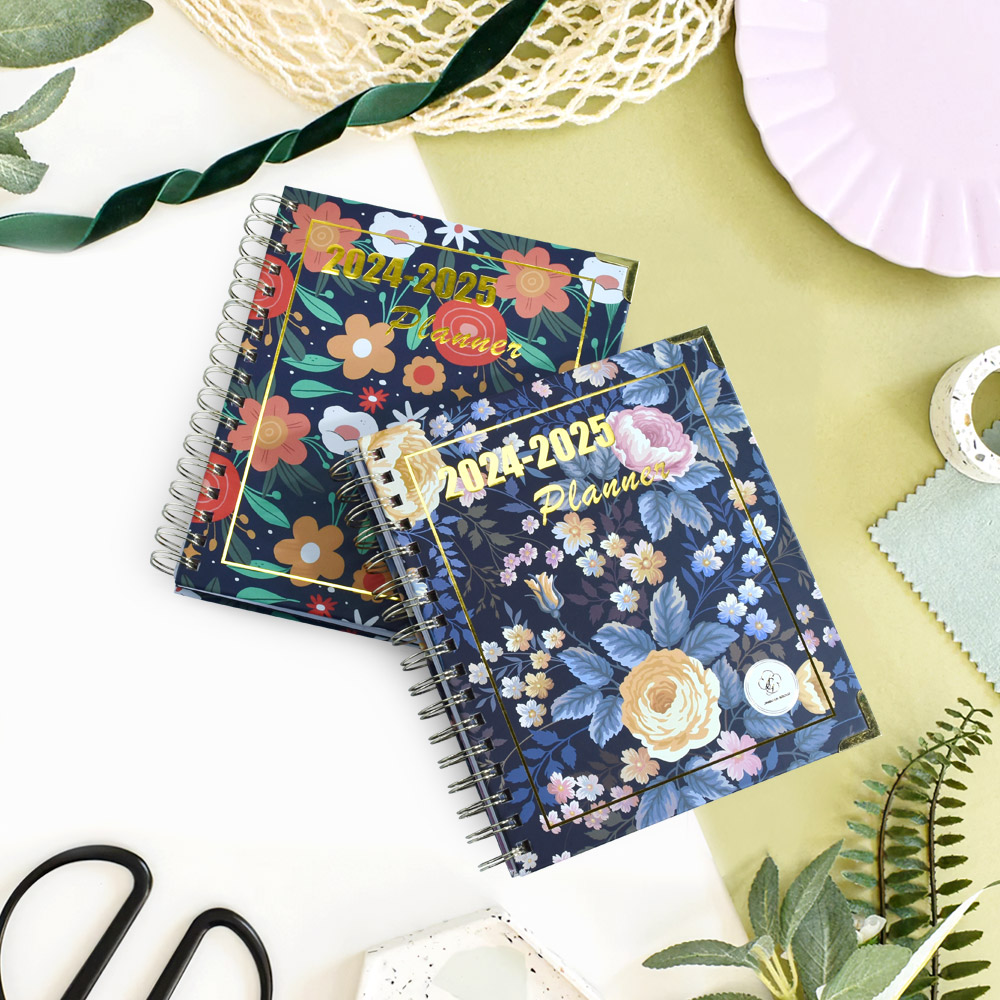

Advanced high-speed inkjet presses now achieve near-offset quality on diverse substrates, enabling custom labels and packaging.

Benefits: By eliminating printing plates and excess inventory, digital printing reduces waste and supports a more sustainable, environmentally friendly production process

How does Digital Printing work?

The first step in digital printing is to send a digital file such as PDF, JPG, etc. to the printer's RIP raster image processor, which converts the image into tiny dots. Then in the inkjet system, micro nozzles eject ink droplets onto the substrate.

In the laser/toner system, the laser charges the drum, which attracts the toner particles and then fuses the toner to the paper through heat.

Since there is no need for a printing plate, every page can be different. Modern high-speed printing presses combine precise ink drop placement or toner fusing technology with advanced color management, allowing short runs, on-demand printing and fast turnaround without the setup time required for traditional printing.

File preparation

Upload digital files, PDF, JPG, etc. to the printer's raster image processor, and the RIP converts the image into tiny dots for printing.

Inkjet printing

The tiny nozzles on the print head spray ink droplets onto the substrate on demand; the position and size of the ink droplets are precisely controlled by digital signals.

Laser/toner printing

The laser scans an electrostatic image on the photosensitive drum, and the toner adheres to the charged area, which is then melted and solidified onto the paper by a heated roller.

No platemaking + variable data required

The whole process does not use traditional printing lead plates or platemaking, so each page can contain different content.

Back-end processing and color management

Modern digital printing systems integrate advanced color correction and back-end packaging, cutting and other functions to achieve a near-offset effect.

Fast and flexible

Save platemaking and machine adjustment time, suitable for short runs, small batches and on-demand printing, and the turnaround cycle can be shortened to a few minutes to a few hours.

Digital Printing vs Offset Printing: Which One is Right for You?

Digital printing and offset printing each have their own advantages. There is no good or bad. You need to choose the printing method that suits your situation.

Digital printing is fast and cheap when the print run is small, such as printing only a few dozen or a few hundred copies. Since there is no need to make metal plates, you can start printing almost immediately.

It is also easy to change individual pages - if you want each print to have a different name or image, digital printing can handle it quickly.

On the other hand, offset printing requires metal plates for each color. First, you need to pay to customize these plates and set up the printing press, which takes time and money at the beginning.

But once everything is ready, the cost per print is greatly reduced. This makes offset printing more economical when thousands of prints are needed.

Offset printing also generally provides sharper details and more consistent colors, so it is often used for large-scale printing jobs such as magazines, product catalogs or large-scale brochures.

In short:

- If you need to print a small number of copies quickly, want each copy to be personalized, or are under time pressure, choose digital printing.

- If you order large quantities and want the best price per copy and consistent color quality, choose offset printing.

This is the core difference between the two: digital printing is fast and flexible for small batches, while offset printing is more cost-effective for large batches.

Materials that can be printed digitally

Ordinary and professional papers

Such as offset paper, coated paper, matte paper, glossy photo paper, art paper, cardboard.

Synthetic and plastic materials

PP, PET, PVC synthetic paper, self-adhesive stickers, transparent films (transparent or frosted), vinyl.

Textiles and fabrics

Polyester, cotton, canvas, silk, etc., can be used for flags, soft films, fabric advertisements, digital photography.

Special boards and hard substrates

Acrylic boards, PVC foam boards, aluminum-plastic boards, KT boards, corrugated cardboard, etc., are commonly used in large-scale printing such as exhibition boards, logos, and display stands.

Other printable materials

Wood chips, metal sheets, glass (special coatings are required), leather (specific inks are required), etc., suitable for crafts, decorations or functional customization.

The above materials need to be selected and tested according to the ink type (UV, solvent, thermal sublimation, etc.) of the digital printer used and the compatibility of the ink with the substrate.

How Digital Printing Enables Custom Packaging for Businesses?

Digital printing allows you to print packaging directly from digital files, without metal plates or long setups.

This means you can order small batches of products, even just a few dozen boxes, without high tooling costs.

Because each design comes from a computer file, you can easily change the artwork for different product versions, add personalized text or QR codes, and make final edits.

Modern digital printing machines can handle a variety of materials—corrugated board, folding carton, laminate—so you get high-quality colors and effects comparable to offset printing.

Turnaround is fast, often just a few days, inventory risk is low, only what is needed is produced, and you can test new designs or seasonal promotions with minimal investment.

In short, digital printing makes customized packaging affordable, flexible, and fast to market.

Speed, Cost, Flexibility: Why More Brands Choose Digital Printing in 2025?

By 2025, digital printing will be the go-to solution for brands that need fast turnarounds.

Modern high-speed inkjet presses can go from file to finished product in just a few days (often 2-3 days for short runs) because there is no need for plates or lengthy press setups.

Such high speeds allow marketers to respond instantly to market changes or seasonal marketing campaigns, avoiding the weeks-long lead times common with traditional printing methods.

From a cost perspective, digital printing eliminates plate and setup expenses, making small runs of 100-1,000 pieces more cost-effective.

Finally, flexibility is a major attraction: variable data printing allows each package or marketing item to be personalized, such as a unique QR code, customer name, or versioned artwork, without the need for additional tooling.

This allows buyers to test multiple SKUs, iterate designs during production, and print on a variety of substrates—corrugated, folding carton, flexible film—with near-offset quality.

In summary, fast delivery cycles, lower upfront costs, and complete customization capabilities are the reasons why more B2B procurement teams will choose digital printing in 2025.

Digital Printing FAQ: Everything You Need to Know Before You Order

Can you print low quantities with Digital Printing?

Digital printing excels at low‑quantity runs because it has no plate or setup fees. You can print as few as one copy, and per‑unit cost stays roughly the same whether you print 1 or 1,000.

What types of files are best for Digital Printing?

PDF (high‑resolution, with fonts embedded or outlined) – preferred for preserving layout and fonts.

TIFF or PNG (300 dpi or higher) – lossless formats ideal for images with transparency (PNG) or maximum quality (TIFF).

EPS or AI (vector-based) – for logos and graphics that need to scale without quality loss.

How do I place an order?

Prepare and proof your artwork in a supported format (PDF preferred).

Choose substrate, finish (matte/gloss/UV coating), and quantity.

Upload files and request a quote or instant online price.

Review digital proof, approve, and complete payment.

Receive order confirmation and estimated shipping date.