You put all your creativity and ideas into every page of your notes, so you don’t want low-quality paper, loose binding, or inconsistent covers to ruin the experience. Buying spiral notebooks wholesale allows you to get more competitive prices without compromising on paper quality, strong binding, and consistent brand style. After reading this guide, you will know exactly which paper is suitable for handwriting, which cover is more in line with your brand positioning, and how to minimize procurement costs while balancing quality and aesthetics.

Table of Contents

1. Five Reasons Bulk Spiral Notebooks Boost Profitability

2. Learn about Spiral Notebook Styles (and When to Use Them)

3. Easily Choose Size and Page Count (No More Guesswork)

4. Dive Deep into Materials: Which Paper and Stiffness to Trust?

5. Customization Steps to Turn Your Notebooks into Your Brand’s Business Cards

6. Sourcing Channels: Compare Your Options

7. Master Pricing and Volume Discount Strategies

8. Warehousing and Handling: How to Protect Your Inventory

9. Final Verdict: Your Ideas + Our Notebooks = Endless Possibilities

1. Five reasons for bulk spiral notebooks to improve profitability

Quantitative economics: lower unit cost

When purchasing 1,000 notebooks, the unit price can be reduced from $2.50 to $1.20. Saving $1.30 is equivalent to saving $1,300 for a batch of 1,000 notebooks. The stationery industry is highly competitive, and reducing costs means increasing profits.

With the increase in purchase volume, not only will the unit price drop, but better payment terms can also be obtained.

Stable quality and less after-sales

After adopting a unified supplier and a unified production process, the paper thickness, coating effect, and spiral line firmness of each batch of goods will remain consistent, reducing the cost of returns and exchanges caused by quality fluctuations.

Quality is controllable and the brand image is more secure.

Improve work efficiency and inventory management

After bulk purchasing, your warehouse can achieve "multiple batches of the same style in one go", and no longer need to replenish stocks from various stationery stores in a piecemeal manner. Save time for searching, comparing, and placing orders, so that more energy can be invested in product planning and sales.

Unified specifications, fast warehousing, and easier employee training and operation.

Supply chain stability

Raw materials in the notebook industry (such as environmentally friendly paper and copper wire) are often out of stock or increase in price during the peak season and the beginning of the semester. Finalize the purchase contract in batches in advance, lock the price and inventory, and you don’t have to increase the price temporarily during the peak season.

For B-end and retailers, stable supply means no missed sales opportunities due to out-of-stock.

Bargaining chips: additional value-added services

When the order volume is large, you can ask the supplier to provide free samples, mold fee reduction, packaging upgrade, expedited production, delayed payment and other value-added services.

These are often difficult to talk about in small orders, such as free layout design, packaging bag printing, and factory inspection reports, which can save you subsequent costs.

2. Understand the styles of spiral notebooks (and when to use them)

Classic paperback spiral

Structure and features: flat cover + metal or plastic spiral binding; cover can be made of kraft paper, PO material or glossy PP; inner pages can be blank, grid, horizontal line or dot matrix.

Applicable scenarios: office meeting minutes, student class notes, daily notebooks.

What you need to care about: paper weight (such as 80gsm, 100gsm) directly affects the writing experience and ink penetration; binding ring diameter determines whether the page is smooth when turning.

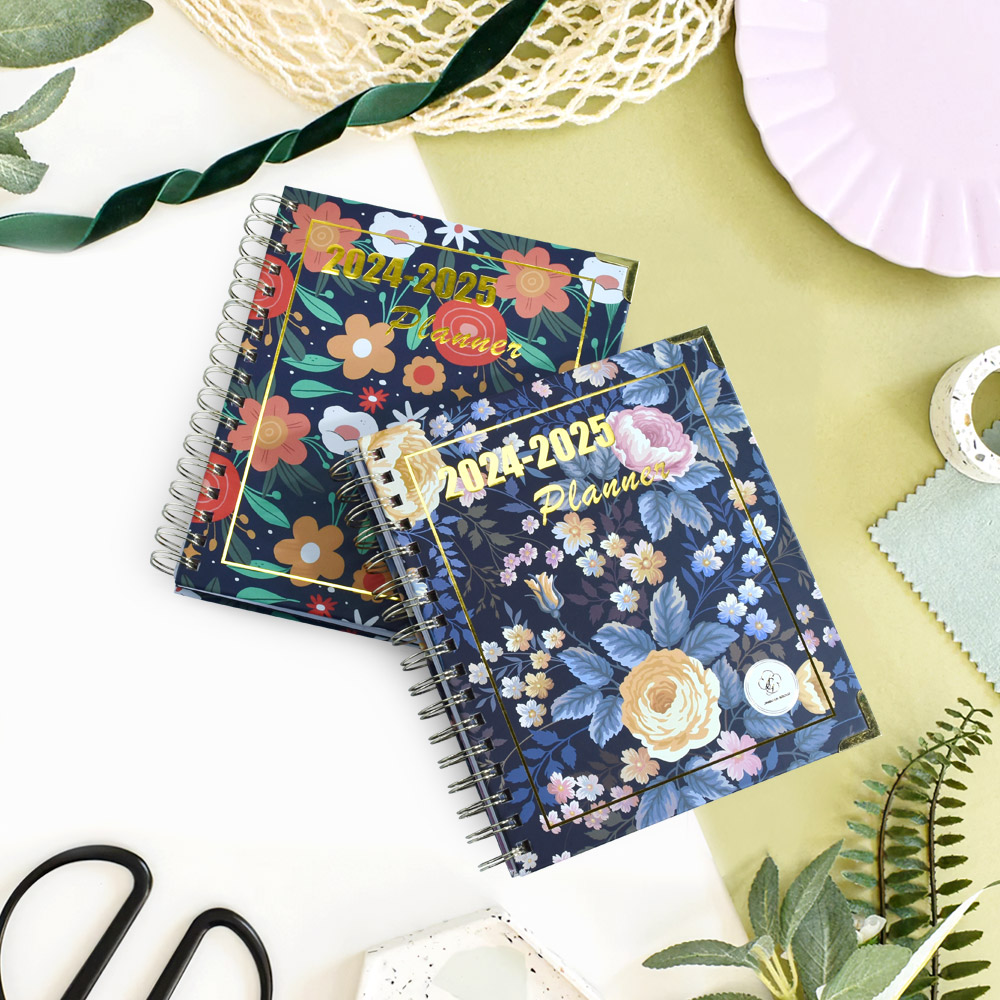

Thickened hard shell spiral

Shell and protection: thick cardboard or PVC hard shell, more resistant to pressure and deformation than ordinary covers; corners are easy to round to prevent bumps.

Applicable scenarios: designer manuscripts, technical manuals, production process drafts; need to be carried many times or shaken in a bag.

Professional tips: If you need to carry it with you frequently and have high requirements for the durability of the cover, the hard shell type can better protect the inner pages from damage.

Page-turning transparent PVC cover book

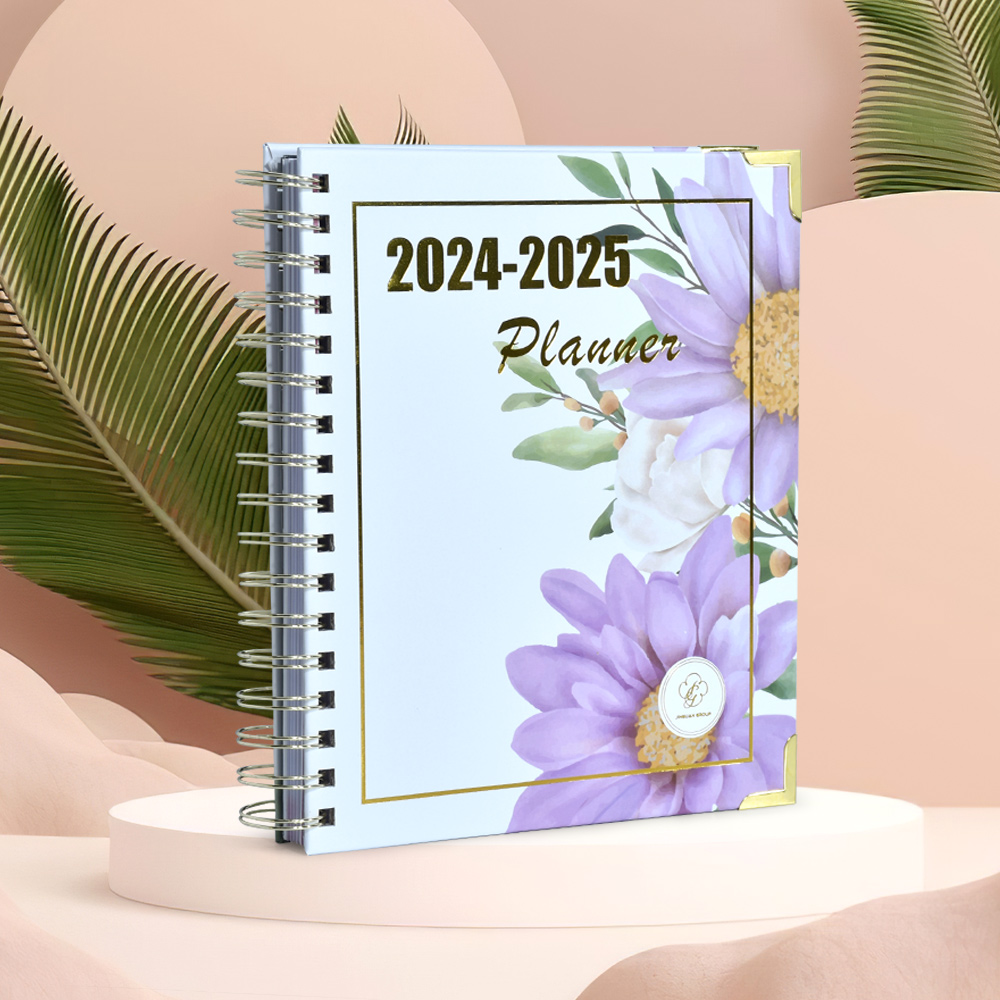

Appearance highlights: PVC semi-transparent cover, inserts or logo paper printing can be placed under the cover to enhance the aesthetics and brand recognition.

Applicable scenarios: university stationery brand customization, gift cultural creation, office gifts; need "packaged" display effect.

You should pay attention: PVC cover is easy to scratch, it is recommended to choose surface film or frosting process to improve texture and durability.

Coil top spiral book

Binding form: spiral at the top of the notebook (horizontally turning pages), the number of pages is usually small, usually about 50-80 pages.

Applicable scenarios: sketchbook, meeting shorthand, to-do list; horizontal writing experience is smoother, suitable for left-handed users.

Purchase points: The diameter and pitch of the top ring should match the number of pages. If it is too small, it will be difficult to turn the page; the page layout can be grid or blank, providing more flexibility.

Additional Function Spiral Notebook

Features: The inner pages have note pages, business card pockets, pen pockets or document pockets; the cover can be equipped with elastic bands or magnetic buckles.

Uses: high-end business gifts, executive manuals, training notebooks; enhance the overall sense of value.

Professional advice: This type of notebook usually has a higher unit price and is suitable for corporate gifts or high-end customization; focus on the environmental protection of materials (such as non-toxic elastic bands and odor-free inner pages).

3. Easily select size and number of pages (no more guessing)

Common size comparison table

| Size Type | International Standard | Typical Use Cases | Common Page Count | Binding Ring Diameter Reference |

|---|---|---|---|---|

| A4 | 210×297 mm | Report Printing, Technical Documents | 100–200 | 20–32 mm |

| A5 | 148×210 mm | Student Notes, Portable Journals | 80–120 | 16–25 mm |

| B5 | 176×250 mm | Office Meetings, Design Sketches | 80–150 | 18–28 mm |

| 8K (198×276 mm) | Common Domestic Size | Creative Gifts, Branded Notebooks | 60–100 | 16–22 mm |

| Pocket Size (approx. 100×140 mm) | Portable Mini Notebook | Short-Term Memos, To-Do Lists | 40–60 | 10–16 mm |

Formula for the relationship between the number of pages and the ring diameter

Formula example:

Binding ring diameter (mm) ≈ number of pages × paper thickness (mm) × 1.2

For example: if the paper is 100gsm (about 0.11mm thick) and you want to bind 100 pages, then the ring diameter ≈ 100 × 0.11mm × 1.2 ≈ 13.2mm, and a ring diameter of 14mm or 15mm is appropriate.

How to choose the number of pages for different purposes

Student use: 120–150 pages are recommended for notes in one semester, and the paper is mainly 70–80gsm; if you need to write more reference materials, 100gsm is recommended.

Designer/painting: 80–120gsm blank paper is commonly used, and neutral pens and markers are not easy to penetrate; if you use watercolor, you can consider 200gsm special lead drawing paper.

Corporate gifts/conference brochures: 80gsm inner pages + 250-300gsm cover, 60-100 pages, customized according to the meeting duration or minutes requirements.

Transportation and delivery notes

If express delivery is required to be delivered to all parts of the country, the paper is prone to warping when exposed to moisture. It is recommended to choose a double-layer plastic bag + cardboard spacer packaging method, or desiccant + vacuum packaging;

For long-distance transportation, try to choose a corrugated box with a compressive strength ≥ 32 ECT (edge compression test) to avoid spiral deformation or cover damage under bumpy road conditions.

4. Dive deeper into materials: Which paper and stiffness can you trust?

| Material Type | Weight/Specification | Advantages | Disadvantages | Eco-Friendliness & Recycling |

|---|---|---|---|---|

| 80gsm Offset Paper | 80 g/m² | Low cost, smooth for handwriting, quick-drying ink | Not suitable for heavy erasing, ink may bleed through | Recyclable, can be made into recycled paper |

| 100gsm Coated Paper | 100 g/m² | Smooth surface, excellent color reproduction, ideal for color printing | Slightly higher cost, adds weight | Recyclable |

| 120gsm Kraft Paper | 120 g/m² | Creates vintage style, unique texture, wear-resistant | Less smooth for writing, not ideal for fine pens | Recyclable, partially reusable |

| 200gsm Art Paper | 200 g/m² | High strength, bleed-resistant, suitable for markers and watercolor | High cost, larger ring diameter required for the same number of pages | Recyclable |

| Plastic PVC Cover | ~200–300 μm thickness | Waterproof, tear-resistant, supports complex printing, durable for repeated use | Not easily degradable, requires separate recycling at designated plastic collection points | Must follow local recycling standards |

| Kraft Paper Hardcover | 250–300 g/m² | Strong compression resistance, solid texture, enhances overall quality | Heavier, increases shipping costs | Recyclable, biodegradable |

Hot Tips:

If you want to take into account both "environmental protection" and "texturedness", you can choose FSC-certified offset paper or 100% recycled kraft paper as the inner pages.

The cover can consider biodegradable composite materials, and use solid color printing + partial UV technology to highlight environmental protection and high-end texture.

For brands that want to create "cultural and creative" or "gift" attributes, consider adding a small amount of customized watermarks or hidden logos to the inner pages, which will not interfere with writing and enhance brand recognition.

5. Customization steps to turn a notebook into a brand name card

Brand color matching and cover design

Pantone color numbers are provided to ensure that the cover printing color is completely consistent with the brand tone;

Special processes: hot stamping, hot silver, embossing, UV glazing, matte/bright film lamination, to add a touch to the cover.

Durable binding and loop selection

Metal ring vs. plastic ring: Metal rings are more resistant to bending and high temperature; plastic rings have rich color options and lower costs.

The loop diameter and pitch (Pitch) must be accurately matched with the number of pages: common pitches are 3:1 and 2.5:1, and the specific parameters need to be communicated with the supplier to avoid page turning jams.

Inner page layout and functional configuration

Layout selection: horizontal lines, grids, dot matrix, blank, calendar, to-do list and other layouts; it is recommended to use different inner page layouts in notebooks for different purposes (for example, "conference books" use horizontal lines + timelines, and "handbooks" use dot matrix + partitions).

Additional functions: add sticky note pages, business card pockets, side holes for easy removal, light watermark logo printed on the inner page writing area.

Interactive elements and personalized value-added

Elastic band + bookmark band: convenient for fixing the cover and marking important pages;

QR code or NFC tag: scan the code to jump to the official website, WeChat public account, online course or coupon page to improve user stickiness;

Limited edition number: for high-end customized models, numbers can be printed on the cover or title page, such as "No. 001-500" to enhance the sense of scarcity.

Packaging and combination sales

Eco-friendly bag/gift box: put one or a set of notebooks into a customized gift box with a brochure or instruction card;

Stationery set: bundled with brand pens, notepads, pens or stickers to increase the average order value;

First order gift: when purchasing in bulk, a customized drawstring cloth bag or storage bag can be given to enhance customer favorability.

6. Procurement channels: Compare your options

Factory (OEM/ODM)

Advantages: most advantageous price, support deep customization, strict quality control;

Minimum order quantity (MOQ): usually from 300-500 copies, depending on the weight of the inner page and the craftsmanship;

Delivery time reference: generally 10-15 working days (including sample confirmation + bulk production);

Suitable for: large stationery brands, school selection, office supplies wholesalers.

Regional dealers/distributors

Advantages: can pick up the goods on the same day, rich SKU variety, no need to stock up in advance;

Disadvantages: higher unit price than factories, limited customization capabilities;

Suitable for: small and medium-sized stationery stores, e-commerce sellers, and cultural and creative studios that are just starting out.

Online wholesale platforms (such as 1688, Alibaba International Station, Made-in-China)

Advantages: Complete categories, quick comparison of multiple suppliers, and user reviews;

Risk warning: There may be color differences between the picture and the actual product. It is recommended to request a "physical sample" or "video shooting" for confirmation;

Suitable for: cross-border e-commerce sellers, small-scale purchases, and cross-category combined purchases.

Finished product brands/cultural and creative platforms (such as Amazon, Etsy)

Advantages: You can directly purchase the "finely decorated version", with a unique style and exquisite packaging;

Disadvantages: High unit price, unable to be deeply customized on demand;

Suitable for: Brand cooperation gifts, festival gift purchases, and small and medium-sized buyers who do not pursue large quantities.

Procurement suggestions

Request samples first: For the most concerned "paper quality", "binding firmness" and "cover craftsmanship", be sure to request physical samples in advance for trial writing and durability testing;

Compare quotations: Compare the "tax-inclusive price", "freight", "tariffs" and "custom service fees" of each channel to ensure the best "final landing price";

Ask about the supplier's qualifications: such as ICC certification, FSC certification, ISO quality management system, etc., to strengthen brand endorsement.

7. Master pricing and volume discount strategies

Common price breakpoints (Breakpoint)

Example: 300 books, 500 books, 1000 books, 5000 books; each breakpoint can strive for a discount ranging from 3% to 8%.

Step pricing: As the volume increases, the cost of a single book decreases in a step-by-step manner. It is recommended to state "5% discount for 500 books, 8% discount for 1000 books, and 12% discount for 5000 books".

Freight optimization: integrated shipment of multiple categories

If you purchase notebooks, folders, calendars, etc. at the same time, you can negotiate with the supplier for "one-stop shipment" and combine the shipment to a single FOB/FCL. For example:

When a single order reaches 20 tons, you can go with full container (FCL), and the sea freight cost can be reduced by about 25%-30%.

If you are a cross-border seller, you can consider the **Haipai + LCL (LCL)** model to save storage costs.

Price index linkage and long-term contract model

It is recommended to sign an index-linked contract with the supplier (such as linked to the "International Waste Paper Index" or "Wood Pulp Price Index") to prevent the risk of "temporary price increases" caused by skyrocketing paper prices.

If you have extremely high requirements for quality and supply stability, you can sign an annual procurement agreement to lock in the price for the whole year in advance and obtain more discounts and priority shipping rights.

Early payment and tiered rebate

Common practice: prepay 30%–50% deposit, and pay the remaining balance within 30 days after production. Suppliers can give 1%–2% discount;

For bulk purchases, you can strive for year-end rebates: if the cumulative purchase volume exceeds 30,000 copies throughout the year, 3% of the total order amount can be returned at the end of the year.

Proofing fee and plate fee control

During deep customization, plate fees will be incurred (such as printing plates for printing covers), and plate fees can be exempted or given "plate discounts" within the range of "500–1000 style copies";

Understand the difference in plate fees between "digital printing" and "gravure printing": digital printing usually has no plate fees, but the unit price is slightly higher; gravure printing is suitable for large quantities and complex layouts, and it can be more cost-effective after the plate fees are amortized over 1,000 copies.

8. Warehousing and handling: How to protect your inventory

Environment and temperature and humidity control

Temperature recommendation: 15–25°C, humidity maintained at 40%–60%. Too high humidity can cause paper to mold and binding rings to rust; too low humidity can cause paper to dry and wrinkle easily.

Dust and insect prevention: Check the warehouse regularly, place desiccant and mildew-proof hanging sheets to prevent insect infestation and paper from getting damp.

Stacking and storage methods

Raise the bottom of the whole box of notebooks by 4-6 inches (10-15cm) to avoid direct contact with the ground and reduce moisture intrusion;

Stacking by light and heavy layers: Put heavy boxes at the bottom and light boxes at the top, and each layer of boxes should not be too high. It is recommended that the stacking height should not exceed 1.2m to prevent the lower layer of boxes from being deformed by pressure.

Inventory shelf life and refurbishment

Spiral notebooks themselves do not have a "strict shelf life", but if stored for a long time (especially plastic rings), the "cover fades" or "plastic becomes brittle" due to ambient light; it is recommended to digest them within 12 months.

For the covers that have been stockpiled for a long time, they can be isolated from ultraviolet rays and checked regularly to avoid long-term pressure on the same part.

Handling and outbound SOP (Standard Operating Procedure)

Employee training: Tongyi teaches employees to "handle and place with care along the crease" and "avoid grabbing the cover directly with the front facing outward" to reduce packaging damage;

Scanning and recording: Scan the barcode or QR code before each box is shipped out, and record the "production batch", "production date" and "supplier" to facilitate traceability when quality problems occur.

Returns and quality inspection

When entering the warehouse, "spot check 3%-5%" of each batch of notebooks: check whether the paper is qualified, whether the binding pitch is consistent, and whether the cover printing is clear;

If problems are found, communicate with the supplier in time within 30 days about the "exchange process" and require an "inspection report" to be attached.

Final conclusion: Your creativity + our notebooks = unlimited possibilities

At this point, you are already familiar with the full process guide from "why to purchase spiral notebooks in bulk" to "how to select models, materials, customization, ordering, and storage". Whether you are a cultural and creative brand, an office supplies distributor, or a school research center, as long as you grasp the key points of materials, binding, cover, pricing, and supply chain management, you can achieve higher profits and brand premiums while ensuring quality and cost control.

Act now:

Request a free sample package: Learn about the real feel of our selected 80gsm/100gsm paper and various cover crafts;

Get a customized quotation: Enter your favorite cover design, inner page specifications and quantity, and we will give you the best solution within 48 hours;

Contact our procurement consultant: No need to pressure inventory, flexible order start, fast proofing, help you seize the first opportunity of the semester, business exhibitions and festival promotions.

Why is the demand for notebook wholesale printing so strong in 2025?

Brand and marketing trends

As brand competition intensifies, more and more companies choose notebook wholesale printing to increase brand exposure.

Customized notebooks can be printed with corporate logos, slogans or unique designs, which are both practical and can continue to spread brand image in conferences, exhibitions and customer giveaways.

Batch printing not only reduces unit costs, but also ensures consistency in color and printing quality, helping marketing activities to achieve higher returns on investment.

Education and institutional orders

The demand for notebooks in schools, training institutions and government departments continues to grow, especially when a new school year or large-scale project is launched.

Wholesale notebook printing can meet the needs of large-scale unified procurement. Different specifications, inner page formats and cover designs can be flexibly combined to meet various application scenarios such as classroom notes, training handouts and meeting minutes. Stable supply capacity and strict quality control are the core considerations for institutional orders.