Selecting the right custom gift box supplier is one of the most important decisions a brand can make—whether you are launching a premium product line, upgrading your packaging for seasonal promotions, or building stronger brand identity through personalized packaging. The packaging industry has evolved rapidly, and today's buyers expect more than just good-looking boxes. They want quality, sustainability, customization, competitive pricing, and reliable lead times.

In this comprehensive guide, you will learn how to evaluate a custom gift box manufacturer, what questions to ask, common mistakes to avoid, and how to compare suppliers based on materials, printing options, and production capabilities. Whether you're searching for luxury rigid gift box suppliers, magnetic closure gift box manufacturers, or low-MOQ custom packaging boxes, this guide provides practical insights to help you make the right decision.

Understand Your Packaging Requirements Before Choosing a Supplier

Before contacting any supplier, clearly define your packaging needs. This step allows you to filter unsuitable factories early and avoid unnecessary communication.

Identify your gift box type

Determine what type of gift box you need because different suppliers specialize in different styles. Common options include:

- Rigid gift boxes

- Foldable gift boxes

- Magnetic closure gift boxes

- Drawer gift boxes

- Lid-and-base gift boxes

- Collapsible gift boxes

- Cardboard gift boxes

- Luxury gift boxes with custom inserts

- Eco-friendly gift packaging

The more specific you are, the easier it is to find a suitable custom gift box factory with the right production line.

Define your customization needs

This helps filter out suppliers who lack certain capabilities.

Consider the following:

- Custom printing (offset, digital, UV)

- Hot foil stamping (gold/silver/holographic)

- Embossing and debossing

- Matte or glossy lamination

- CMYK and Pantone color matching

- Custom paper types and thickness

- Magnetic or ribbon closure

- Foam, EVA, or cardboard inserts

- Window cut-outs

If your packaging requires premium finishes, make sure the supplier has strong craftsmanship, especially for luxury brands.

Know your budget and MOQ

Every manufacturer has different MOQ requirements:

- Some offer low MOQ custom gift boxes for small businesses.

- Others only accept large orders due to machine setup costs.

Define your acceptable:

- Unit price range

- Order quantity

- Packaging budget

- Shipping preference (air, sea, or express)

Evaluate the Supplier's Production Capabilities

Not all suppliers have the same level of technology, equipment, or expertise. Choosing one with proper technical competence ensures your packaging meets your quality standards.

Check if they are a factory or a trader

Factories offer:

- Better pricing

- Faster production

- Stable quality control

- Custom engineering solutions

- On-site production photos or videos

Traders may be acceptable for simple packaging, but for luxury custom gift boxes, working directly with a manufacturer is always better.

Review machinery and production lines

Advanced suppliers usually have:

- Automatic rigid box machines

- Die-cutting machines

- High-precision laminators

- Hot stamping machines

- Offset printing machines

- 3D UV printers

- CNC foam cutting equipment

A capable supplier can produce more consistent and accurate luxury rigid boxes, especially for high-end cosmetics, jewelry, electronics, or gifts.

Ask about quality control

A trustworthy supplier conducts:

- Incoming raw material inspection

- Printing color check

- Glue strength testing

- Drop tests for shipping durability

- Final QC with multiple checkpoints

Consistent QC ensures your custom packaging gift boxes maintain uniform quality across all batches.

Evaluate Material Quality and Printing Accuracy

The material determines how the customer perceives your product. The printing determines how professional the packaging looks.

Paper and board selection

Reputable suppliers offer many material choices such as:

- Kraft paper

- Coated art paper

- Textured paper

- FSC-certified recycled paper

- Greyboard from 800–2000 gsm

- Specialty papers (linen, leather texture, pearl paper)

Better materials offer more durability and a premium feel.

Printing quality

Ask the supplier to share samples demonstrating:

- Pantone color consistency

- Image sharpness

- No smudging

- Smooth lamination

- Metallic foil clarity

- Clean embossing and debossing

Good printing is essential for branding and customer perception.

Assess Communication, Professionalism, and Service

A supplier's attitude tells you a lot about their reliability.

Responsiveness

A good supplier replies quickly with:

- Professional answers

- Clear quotations

- Accurate timeframes

- Technical suggestions

Slow communication is a red flag.

Experience in your industry

If the supplier has worked with:

- Beauty and cosmetics brands

- Jewelry brands

- Clothing brands

- Food & chocolate brands

- Electronics and gadget brands

They will understand your packaging requirements better.

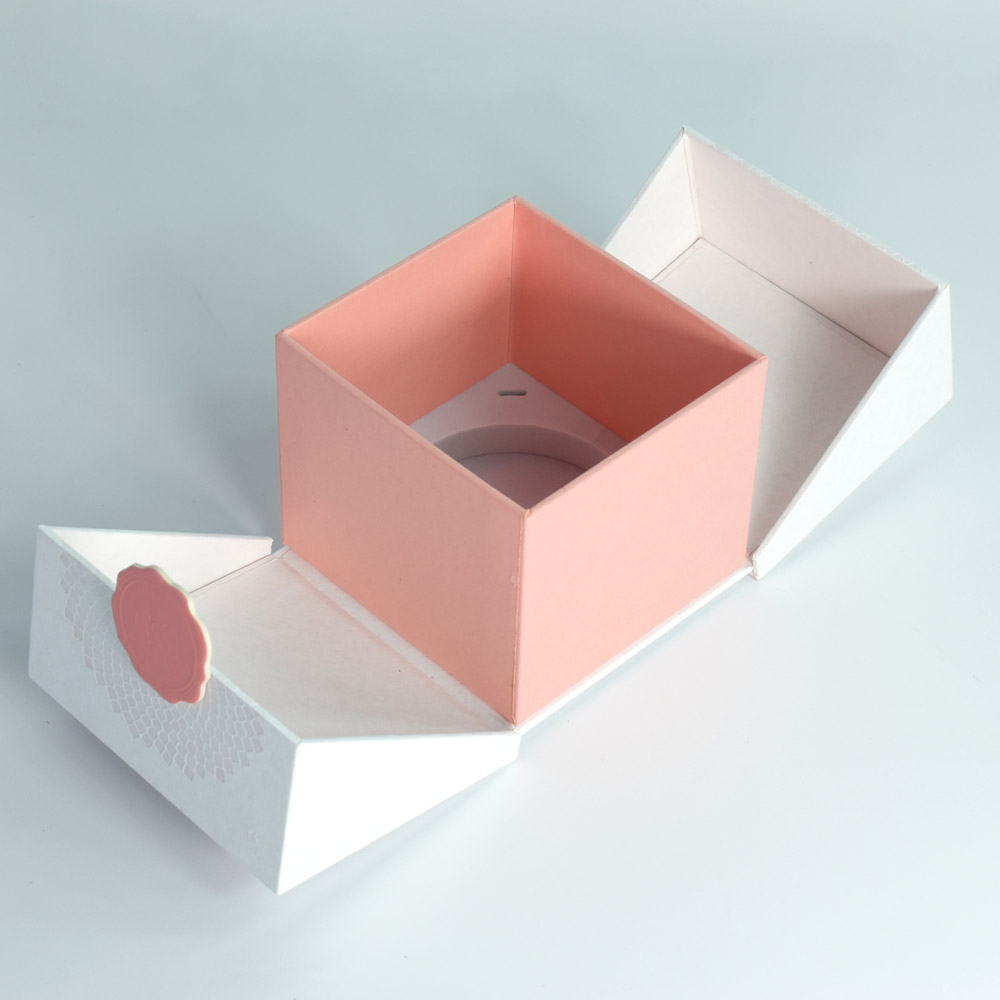

Ability to provide structural design

A strong supplier can offer:

- 3D mockups

- Dieline templates

- Packaging suggestions

- Structural improvements

This is crucial for brands scaling new products.

Compare Prices, Lead Times, and Shipping Options

Pricing transparency

Compare multiple quotations, paying attention to:

- Unit cost

- Mold or tooling fees

- Insert cost

- Packaging and carton fees

- Sample fees

- Shipping cost

Avoid suppliers with vague or ''too good to be true'' pricing.

Production time

Typical production timelines:

- Sample: 3–7 days

- Mass production: 15–30 days

- Peak season (Nov–Jan): longer

Shipping options

Reliable suppliers provide:

- Sea freight

- Air freight

- Express delivery

- DDP shipping

For bulk packaging, sea freight is most economical.

Check Reviews, Certifications, and Past Projects

Ask for:

- Customer testimonials

- Case studies

- Certifications (FSC, ISO, SGS)

- Previous luxury packaging projects

This helps you judge whether they are capable of delivering high-end custom gift boxes.

Order Samples Before Confirming the Supplier

Never place a large order without reviewing samples.

Evaluate:

- Structural strength

- Printing clarity

- Lamination quality

- Logo finishing

- Magnet strength

- Insert accuracy

Samples reveal whether the supplier meets your expectations.

Why Many Brands Prefer Working With Jinguan

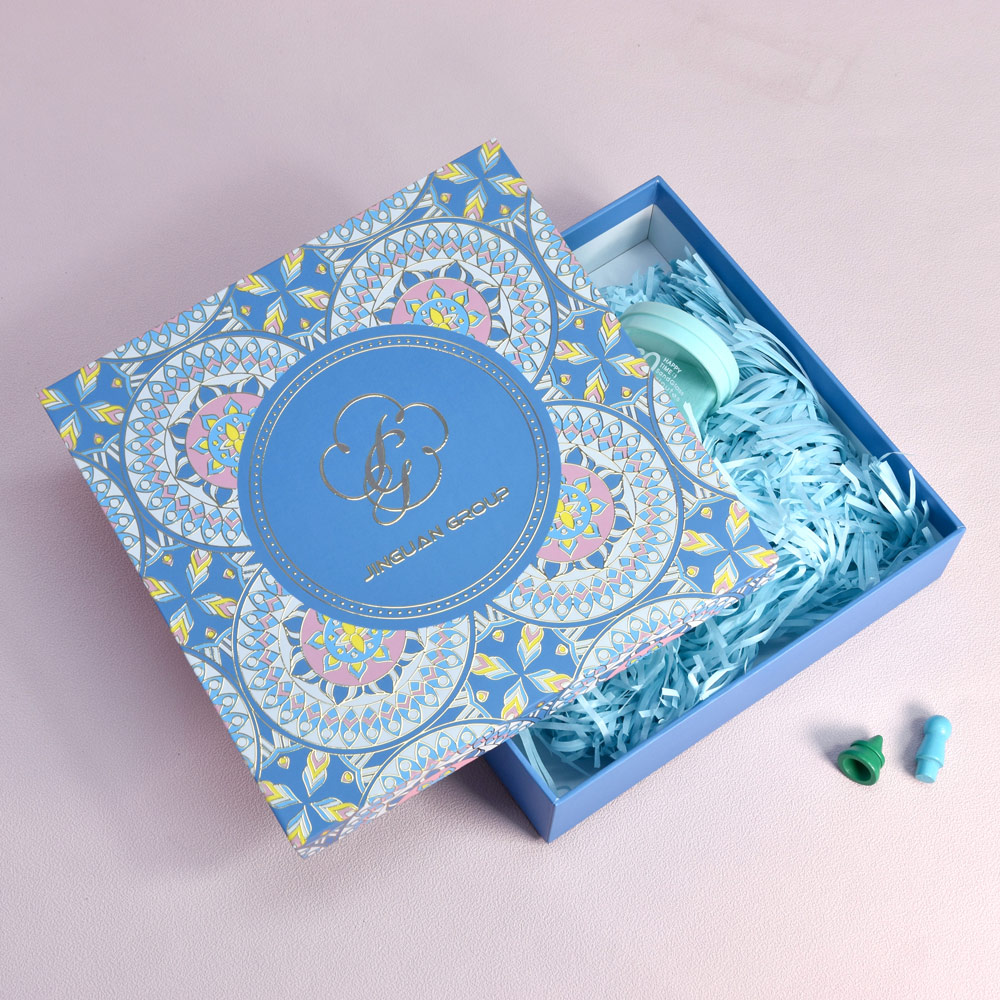

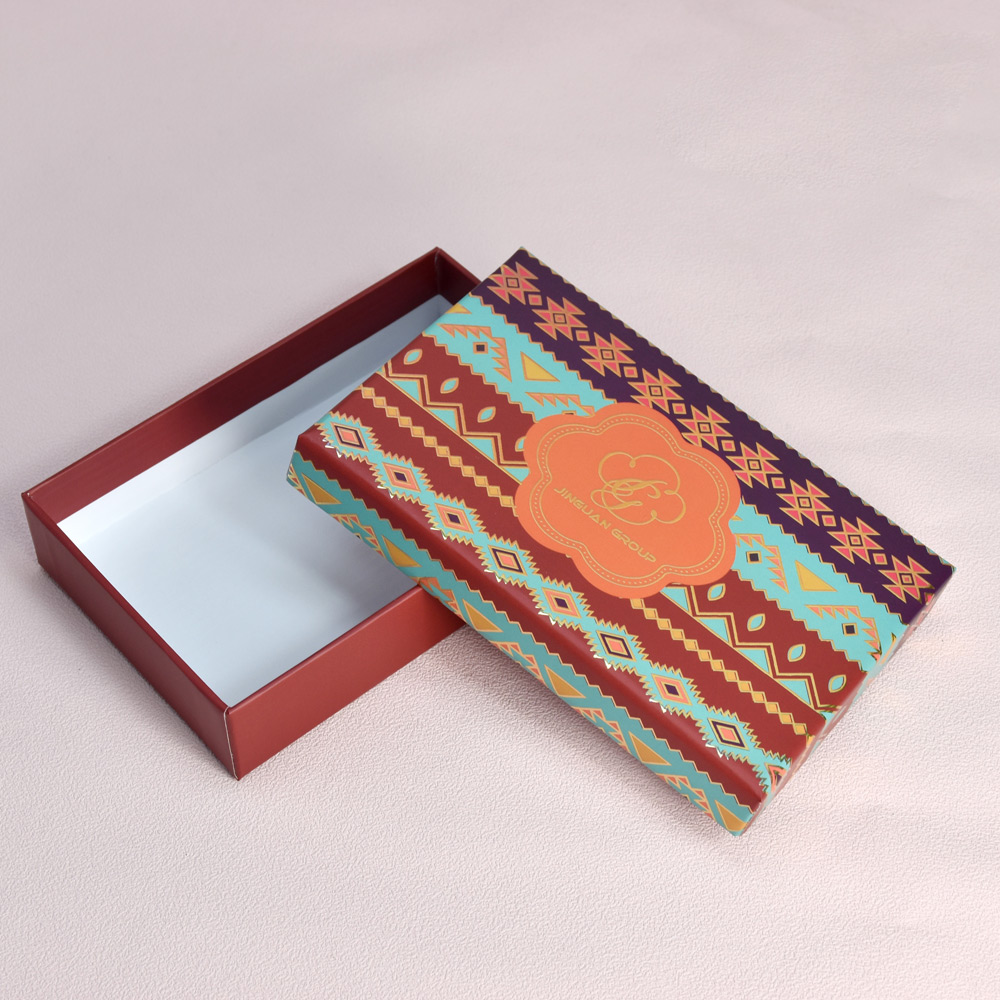

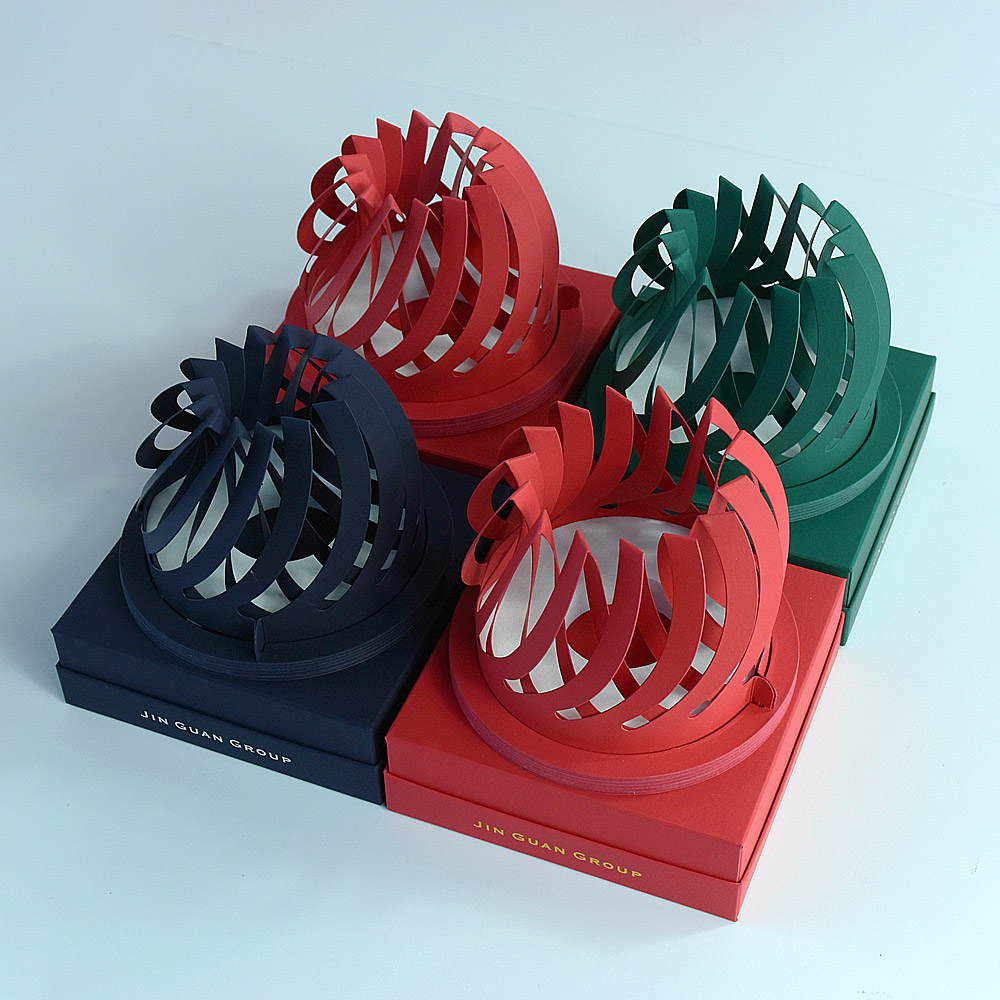

In the custom gift box industry, many international buyers work with suppliers that offer a balance of professionalism, production capacity, and stable quality. Companies like Jinguan have built good reputations for manufacturing:

- Luxury rigid gift boxes

- Magnetic closure gift boxes

- Collapsible rigid boxes

- Drawer gift boxes

- Custom printed cardboard packaging

What many customers appreciate is that Jinguan focuses on consistent craftsmanship, customized packaging solutions, and flexible order support. While you should always evaluate suppliers based on your own needs, Jinguan is often considered by brands looking for reliable custom gift box manufacturing in China.

Final Tips: How to Avoid Common Mistakes

Avoid these pitfalls when selecting a supplier:

- Choosing the lowest price

- Not checking digital proofs

- Not clarifying color matching

- Ignoring shipping costs

- Not checking insert accuracy

- Not requesting pre-production samples

Selecting a supplier isn't just about price—it's about long-term partnership.

Conclusion

Choosing the right custom gift box supplier requires careful evaluation of materials, craftsmanship, production capacity, communication, pricing, and delivery reliability. Whether you need luxury rigid boxes, magnetic gift boxes, eco-friendly gift packaging, or custom printed cardboard boxes, taking time to assess your options will help you find a reliable partner.

Professional suppliers—such as Jinguan, known for dependable production and custom solutions—can help brands upgrade their packaging quality, improve customer experience, and reinforce branding through well-designed, high-quality gift boxes.

If you follow all the guidelines above, you will confidently find the best supplier for your business.