Custom gift boxes have evolved from simple packaging to an essential element of modern branding, marketing, and customer experience. In today's competitive market, a product's packaging often determines first impressions, perceived value, and repeat purchase behavior. According to recent industry reports, the global gift box packaging market is projected to reach $11.5 billion by 2025, growing at a CAGR of 5.8% driven by e-commerce, luxury goods, and corporate gifting.

Custom gift boxes not only protect products but also provide a luxurious unboxing experience, reinforce brand identity, and reflect a company's commitment to quality and sustainability. Brands across cosmetics, jewelry, electronics, and fashion rely heavily on specialized packaging to differentiate themselves from competitors.

This comprehensive guide covers everything you need to know about custom gift boxes—types, materials, designs, production processes, supplier selection, cost considerations, and trends. It also naturally links to more in-depth articles, including:

- Magnetic Gift Boxes vs Traditional Gift Boxes: Which Is Better?

- Top 10 Gift Box Manufacturers in 2025

- How to Choose a Custom Gift Box Supplier

- Magnetic Gift Boxes: Benefits, Uses, and Popular Designs

By following this guide, you will gain expert knowledge to choose the perfect custom gift box that aligns with your product, brand, and customer expectations.

Table of Contents

- What Are Custom Gift Boxes?

- Main Types of Custom Gift Boxes

- Materials Used in Custom Gift Boxes

- Popular Designs & Structural Styles

- How to Choose the Right Custom Gift Box

- Best Custom Gift Box Suppliers

- Custom Gift Box Manufacturing Process

- Cost Factors & Pricing

- Applications of Custom Gift Boxes

- Trends & Future Development

- Conclusion

- FAQs

What Are Custom Gift Boxes?

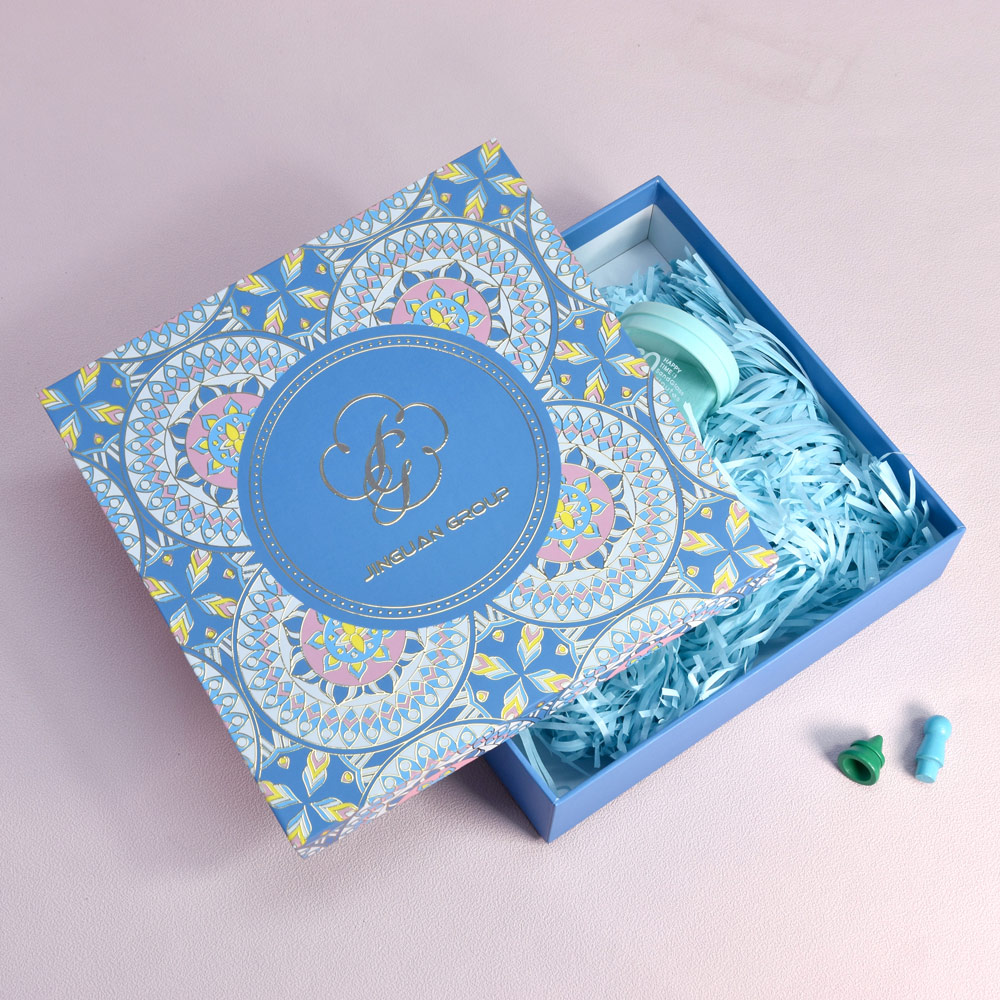

Custom gift boxes are tailor-made packaging solutions designed to enhance product presentation, brand recognition, and customer experience. Unlike stock boxes, they are engineered for specific dimensions, materials, and structural features. They can include magnetic closures, embossed logos, soft-touch finishes, and specialty inserts that elevate the perceived value of the product inside.

Businesses invest in custom gift boxes for several reasons:

- Brand differentiation: Unique packaging helps products stand out on shelves and online marketplaces.

- Product protection: Properly designed boxes prevent damage during transport, storage, and handling.

- Enhanced unboxing experience: Well-designed packaging contributes to customer satisfaction and loyalty.

- Marketing and storytelling: Packaging communicates brand values, sustainability, and luxury positioning.

Main Types of Custom Gift Boxes

Custom gift boxes come in various types, each suited to specific products, budgets, and branding goals.

Magnetic Gift Boxes

Magnetic gift boxes are premium packaging solutions featuring integrated magnets for a secure closure. They are ideal for luxury jewelry, cosmetics, electronics, and corporate gifts. Magnetic boxes offer a clean, elegant unboxing experience and are often reused by customers, which reinforces brand visibility.

Benefits include:

- High-end look and feel

- Durability and reusability

- Compatibility with embossing, foil stamping, and soft-touch lamination

For a detailed discussion, see: → [Magnetic Gift Boxes: Benefits, Uses, and Popular Designs]

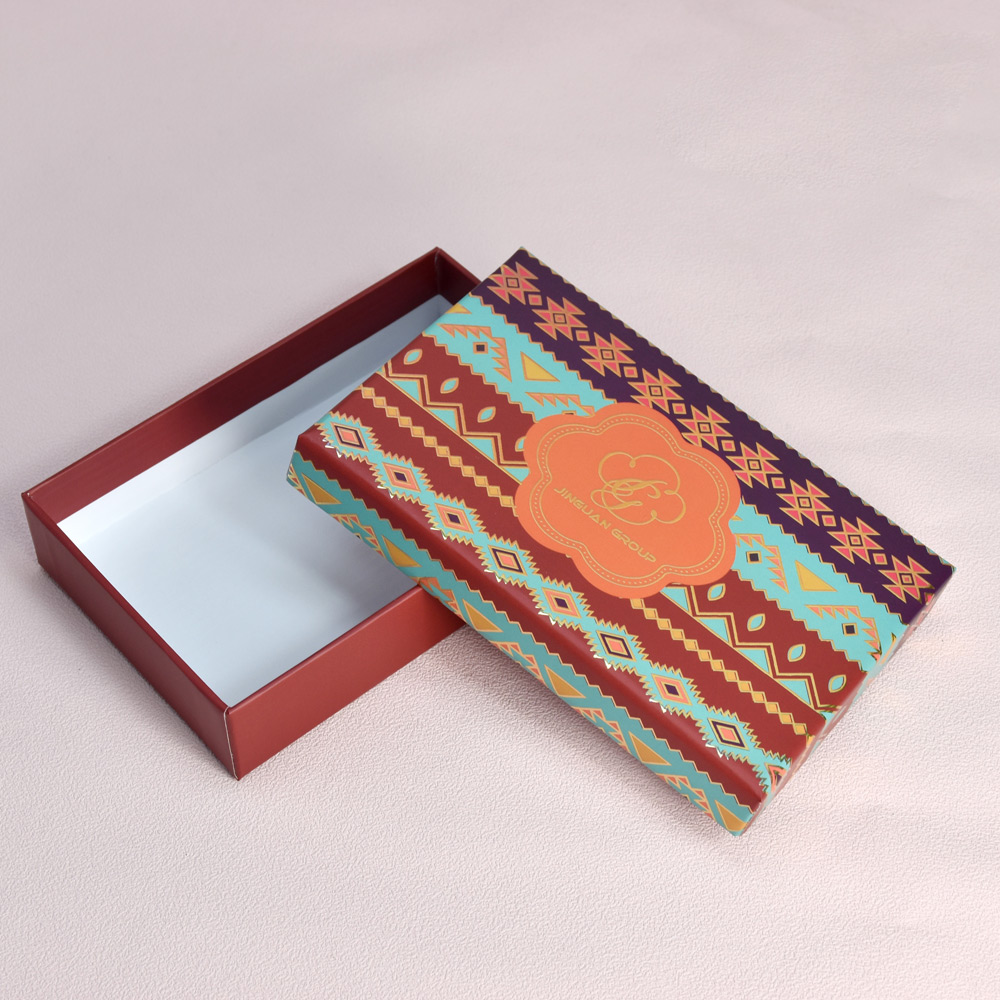

Rigid Gift Boxes

Rigid boxes are made from thick greyboard or paperboard (800–2000 gsm), wrapped with specialty paper. They are known for their durability and premium appearance, making them suitable for watches, luxury electronics, and high-end cosmetics. Rigid boxes provide structural integrity and often include magnetic or friction-fit closures.

Foldable Gift Boxes

Foldable boxes are cost-effective and space-saving. They can be shipped flat and assembled as needed. While not as sturdy as rigid boxes, foldable designs are ideal for retail promotions, subscription boxes, and seasonal products. They support high-quality printing, laminates, and inserts for a polished look.

Drawer Boxes

Drawer boxes feature a sliding tray inside a sleeve, creating a distinctive unboxing experience. They are widely used for luxury stationery, cosmetics, gift sets, and accessories. Custom inserts such as EVA foam or cardboard dividers enhance product protection.

Corrugated Gift Boxes

Corrugated boxes are strong and lightweight, designed for shipping heavier or fragile products. They are often used for electronics, subscription boxes, and e-commerce shipping. Corrugated boxes can be printed in full color or combined with Kraft paper for sustainable branding.

Kraft Boxes

Kraft boxes are eco-friendly, made from recyclable and biodegradable paper. They are commonly used for organic products, food, and corporate gifts, offering a rustic and sustainable appearance. Kraft boxes can be customized with ribbons, window cut-outs, or stamped logos.

Magnetic vs Traditional Gift Boxes

Comparing magnetic boxes with traditional boxes helps brands make informed decisions:

| Feature | Magnetic Boxes | Traditional Boxes |

| Structure | Rigid with magnetic flap | Foldable or lid-and-base |

| Durability | High | Moderate |

| Brand Appeal | Premium | Standard |

| Cost | Higher | Lower |

→ [Magnetic Gift Boxes vs Traditional Gift Boxes: Which Is Better?]

Materials Used in Custom Gift Boxes

Material selection determines the quality, durability, and aesthetic of a gift box.

- Rigid Paperboard / Greyboard (800–2000 gsm): Provides structure and strength.

- Art Paper / Specialty Paper: Matte, glossy, metallic, soft-touch, linen, pearl finish.

- Kraft Paper (70–250 gsm): Eco-friendly and versatile.

- Corrugated Cardboard: Suitable for shipping or subscription packaging.

- Inserts: EVA foam, molded pulp, PET trays, or cardboard dividers.

Material choice impacts print quality, lamination compatibility, and tactile experience. Brands like Jinguan offer high-quality materials with precise thickness and finishes to ensure premium presentation.

Popular Designs & Structural Styles

Gift box design includes functional structure and visual aesthetics:

- Magnetic Closure Boxes: Premium feel, secure, reusable

- Lift-off Lid / Two-Piece Boxes: Classic design, versatile

- Drawer / Sliding Boxes: Unique unboxing experience

- Collapsible / Foldable Boxes: Cost-effective and space-saving

- Window Cut-Outs: Display products without opening

- Finishes: Matte, glossy, soft-touch, foil stamping, embossing

Professional design combines structural integrity with brand storytelling. 3D mock-ups and die-line prototypes are often used to ensure accuracy before mass production.

How to Choose the Right Custom Gift Box

Choosing the correct custom gift box involves careful evaluation of several factors:

- Product Specifications: Weight, size, fragility

- Structure and Closure Type: Magnetic, lift-off, drawer, or foldable

- Material Selection: Thickness, laminates, coating

- Printing and Finishing Options: CMYK, Pantone, embossing, hot foil stamping

- Brand Alignment: Color, texture, and logo presentation

- MOQ and Lead Time: Ensure supplier can meet demand

- Supplier Credentials: Certifications (ISO, FSC), QC procedures

- Cost Considerations: Balance between perceived value and budget

For a step-by-step guide, see: → [How to Choose a Custom Gift Box Supplier]

Best Custom Gift Box Suppliers

Selecting a reputable supplier is crucial. Consider:

- Global production capacity and OEM/ODM services

- Advanced printing and finishing capabilities

- Proven track record with international brands

- Quality control standards and certifications

For a curated list of top manufacturers: → [Top 10 Gift Box Manufacturers in 2025]

Custom Gift Box Manufacturing Process

Manufacturing involves multiple steps:

- Design & Prototyping: Die-lines, structural mock-ups, 3D renders

- Printing: CMYK, Pantone spot colors, embossing, foil stamping

- Cutting & Folding: Die-cutting, creasing, folding

- Lamination & Coating: Matte, gloss, soft-touch, anti-scratch

- Assembly & Inserts: Box assembly, magnetic closure installation

- Quality Control: Edge alignment, color matching, closure testing

Professional factories ensure consistent product quality and premium appearance.

Cost Factors & Pricing

Key cost factors include:

- Material costs (paper, board, laminates, inserts)

- Printing and finishing complexity

- Box structure and size

- Production volume (MOQ impact on unit price)

- Labor for assembly and packaging

- Shipping and logistics

Example: A magnetic rigid box with embossing and foam insert may cost 2–3x more than a foldable Kraft box but significantly enhances perceived value.

Applications of Custom Gift Boxes

Custom gift boxes serve diverse industries:

- Cosmetics: High-end skincare, perfume, makeup sets

- Jewelry & Watches: Reinforce luxury perception

- Electronics: Gadgets, headphones, smart devices

- Apparel & Accessories: Fashion products and gift sets

- Luxury Food & Beverages: Chocolates, wines, artisanal goods

- Corporate Gifts & Event Packaging: Branded boxes for marketing campaigns

- Subscription Boxes: Curated monthly products with durable packaging

Trends & Future Development

Emerging trends include:

- Sustainable Packaging: Recyclable materials, FSC-certified boards

- Smart Packaging: QR codes, NFC chips for product info and engagement

- Minimalist Design: Clean lines, matte finishes, subtle branding

- Premium Unboxing Experience: Magnetic closures, soft-touch laminates, embossed logos

- Advanced Printing Technologies: Metallic, holographic, and tactile finishes

Conclusion

Custom gift boxes are more than packaging—they define the first impression of a product. Choosing the right type, material, and design ensures durability, aesthetic appeal, and a memorable unboxing experience. Magnetic boxes offer elegance and reusability, rigid boxes convey premium quality, while Kraft or foldable boxes balance cost and sustainability. Thoughtful selection and execution of gift boxes enhance brand perception, protect products, and leave a lasting impression on customers.

For businesses looking for high-quality, customizable solutions, Jinguan offers a wide range of custom gift boxes with premium materials, professional finishes, and flexible designs to meet your brand's unique needs. Explore our collection today and create packaging that truly stands out.

FAQs

Q1: What is the most popular type of custom gift box?

A1: Magnetic rigid boxes and high-quality rigid boxes are currently the most popular for premium products.

Q2: How do I select the right material for my gift box?

A2: Consider product weight, protection needs, aesthetics, and sustainability goals. Greyboard with specialty laminates is ideal for luxury products.

Q3: Are magnetic gift boxes reusable?

A3: Yes, magnetic closures make them durable and reusable, which increases brand exposure.

Q4: What is the minimum order quantity (MOQ)?

A4: MOQs vary by supplier, typically between 500–1000 units depending on size and complexity.

Q5: How long does production take?

A5: Production usually takes 10–20 business days, depending on quantity, complexity, and finishing.

Q6: Can custom gift boxes be eco-friendly?

A6: Yes, Kraft boxes and FSC-certified materials allow brands to minimize environmental impact while maintaining quality.

Q7: How can I add a premium feel without increasing costs drastically?

A7: Using soft-touch lamination, embossing, or foil stamping on smaller areas can enhance perceived value without significantly raising costs.