Board book printing for toddlers plays a fundamental role in early childhood education. Unlike standard books, board books must handle rough use, chewing, bending, and repetitive page turning. Parents and educators expect toddler board books to be safe, durable, and visually engaging. Publishers and self-publishing authors need to understand safety standards, printing materials, and binding options before moving into production.

High-quality board book manufacturing ensures child safety while strengthening brand credibility and long-term product value.

Why Safety Standards Matter in Toddler Board Book Printing

Toddlers explore books with their hands and mouths. Poor-quality finishes or unsafe materials can pose choking or poisoning risks. Every custom baby board book must guarantee:

- Non-toxic inks and food-grade adhesives

- Rounded corners to prevent injuries

- Smooth surfaces without cracking

- Tear-resistant pages for extended use

- Certifications proving the book is safe for infants and toddlers

Safety is not just a feature; it is a legal requirement.

Global Safety Regulations for Children's Board Books

Publishers often sell globally, so compliance is essential. Common regulatory standards include:

Major Child Product Regulations

- ASTM F963 (United States)

- CPSIA regulations on lead and phthalate content (United States)

- EN71 parts 1–3 (European Union)

- REACH restricted substances (European Union)

- ISO 8124 (International safety testing)

These ensure a child-safe board book that meets market requirements without the risk of customs rejection or product recalls.

Safe Printing Materials Used in Toddler Board Books

Paperboard Options

The most popular material is SBS board (Solid Bleached Sulfate) Advantages include rigidity, clean printing performance, and odorless composition.

Ink and Coatings

Water-based inks: non-toxic, safe if mouthed

Water-based varnish or eco matte lamination: prevents smudging and provides child-friendly touch

Binding Adhesives

- Non-toxic, food-safe glue keeps pages secure even if bitten.

- Using the right materials directly determines product safety and market approval.

Durability Considerations in Board Book Printing

Quality board books must endure daily use in homes and classrooms. Key durability factors include:

- Page thickness options like 1.5mm, 2mm, 2.5mm

- Board-to-board binding for stronger binding strength

- Scratch-resistant coatings

- Reinforced edges to avoid delamination

Premium toddler board book manufacturers focus on long-term reliability, not just initial appearance.

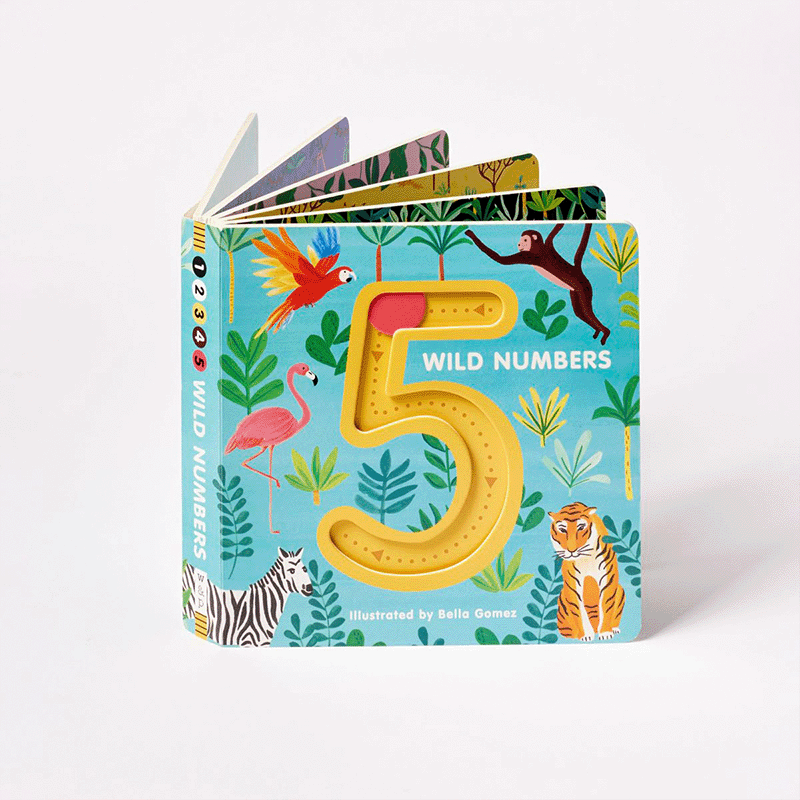

Popular Board Book Types for Toddlers

Different formats enhance reading engagement and learning outcomes:

- Standard board books with simple stories

- Early learning books with alphabets, shapes, and first words

- Touch-and-feel sensory books with textures

- Lift-the-flap board books for interaction

- Die-cut shaped books for playful reading

- Puzzle board books with detachable pieces

- Sound/light books for multi-sensory development

Customization gives brands creative freedom for educational goals and commercial positioning.

Sustainable and Eco-Friendly Board Book Printing

Parents increasingly prefer environmentally friendly children's books. Sustainable options include:

- FSC-certified paper

- Soy-based or water-based inks

- Recyclable board materials

- Reduced-plastic laminations

A commitment to safety should extend not only to children, but also to the planet they grow up in.

Color Accuracy and Printing Quality for Toddler Learning

Toddlers rely heavily on color perception during early development. High-quality offset printing ensures:

- Bright, eye-catching visuals

- Pantone or CMYK accuracy across batches

- Protective finishing for long-lasting color

Strong visual appeal increases educational value and product desirability.

Production Workflow Overview

A professional board book printing factory follows critical manufacturing stages:

- Prepress file check and proofing

- Offset printing

- Lamination

- Die-cutting

- Collation and binding

- Corner rounding

- Strict quality inspection

- Secure packaging

Every step must be controlled to protect child safety and ensure consistent quality.

How to Choose a Reliable Board Book Printing Supplier

When evaluating a partner, ensure they:

- Have experience with child-safe product compliance

- Offer safety testing and reports

- Provide expert guidance on structure and materials

- Support small-batch and mass production

- Maintain strong quality control systems

A dependable manufacturer prevents legal issues and enhances your brand reputation.

Why Many Brands Choose Jinguan

With over 21 years of OEM and on-demand printing experience, Jinguan provides customized solutions for global children's publishers and educational brands. Jinguan specializes in:

- Custom board book printing for toddlers

- Child-safe materials meeting ASTM and EN71 standards

- Durable structures designed for heavy toddler use

- Vibrant color results via professional offset printing

- Flexible customization including unique shapes and interactive features

- Small to large production volumes for various business stages

- Eco-friendly printing options available

Jinguan ensures your board books are safe, engaging, and retail-ready for international distribution.

Conclusion

Board book manufacturing is more than printing pages. It requires strict safety compliance, durable construction, and thoughtful material selection, especially when products are targeted at toddlers. As demand for early learning products continues to grow, publishers who prioritize reliable production gain market trust and competitive advantages.

By partnering with experienced manufacturers such as Jinguan, your board books will be compliant, visually captivating, and built to last, supporting both education and brand success.